Contents | 1. Introduction to structural design | 2. Loads |

Introduction to wood | Material properties | Sectional properties | Design approaches |

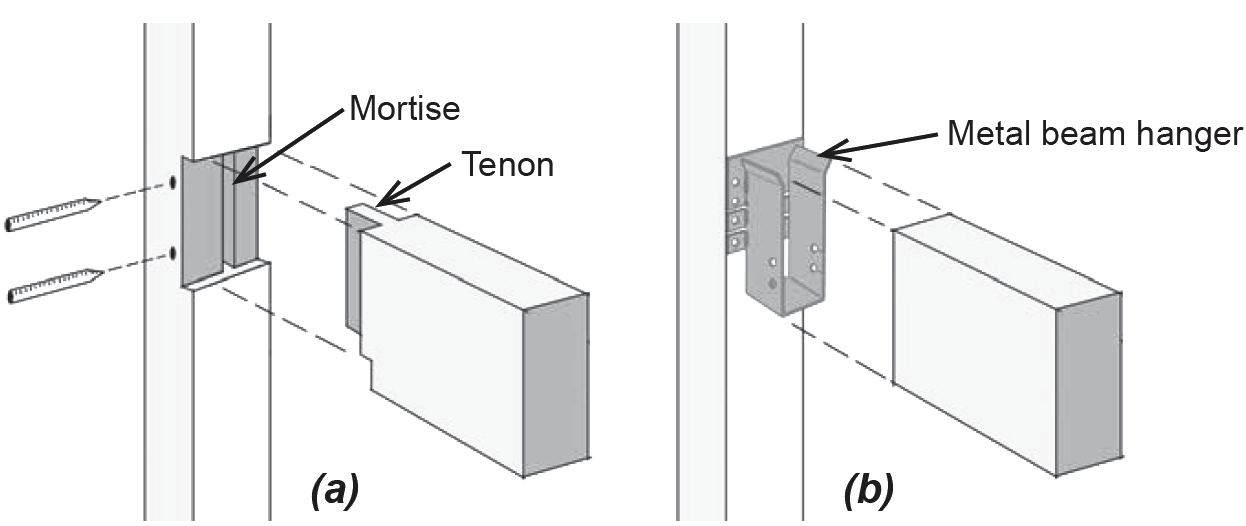

Timber framing systems using large wooden cross sections were prevalent in both Western and Eastern cultures up until the invention of balloon framing (subsequently modified into "platform framing") in the mid-nineteenth century. A typical timber framing joint characteristic of such traditional framing involved a high degree of skill and craftsmanship; today, connections of large, or even small, cross sections often rely on metal fasteners (Figure 3.11).

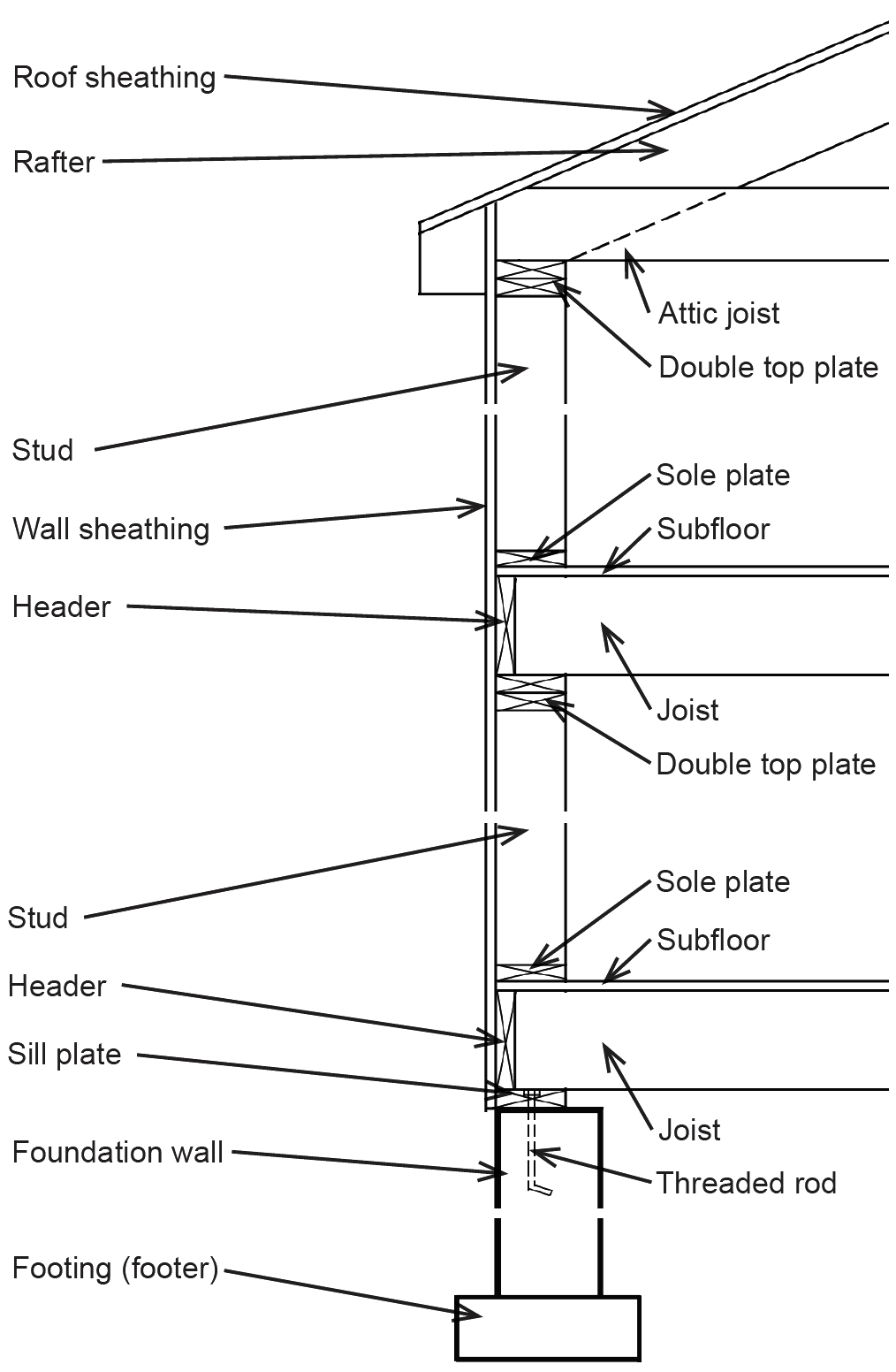

Balloon framing was invented in the U.S. in the mid-nineteenth century and consists of wood elements with small cross sections (what we now call "dimension lumber") configured in the wall as plates (horizontal) and studs (vertical); and in the floors and roofs and joists and rafters respectively. The strength and stiffness of such systems relies on diaphragm action in the walls and floors, created by nailing sheathing (walls) and subfloors (floors) to the studs and joists. In traditional balloon framing, diagonal wood members were "let into" the walls to provide lateral stability; in modern construction, plywood (or OSB) sheathing creates so-called "shear walls" without any diagonal elements required.

Platform framing is a modification of balloon framing and is the prevalent mode of light wood framing today. The main difference between the two systems is that in balloon framing, vertical studs are continuous from foundation to roof, whereas in platform framing, studs are interrupted at each floor level by the floor construction. Platform framing has two advantages over balloon framing: studs are only one story high, so long pieces of lumber are not required, and wall sections can be fabricated on the floor platforms in a horizontal position, and then easily lifted (or tilted) in place.

The main disadvantage of platform framing compared to balloon framing is that platform framing interrupts the continuity of vertical studs with joists and plates oriented with their grain perpendicular to the direction of loads, so that expansion or contraction along the exterior wall surface may be greater at those points. This issue was discussed earlier (see Figure 3.5) in relation to unintended sloping of floor joists; it also should be considered when relatively rigid siding materials, such as brick veneer, are fastened to exterior studs. In such cases, the differential movement where floors intersect the vertical studs should be accommodated with "soft" joints in the brick veneer.

U.S. building with dimension lumber is based on a 4-foot (48-in.) structural module, subdivided either into 16-in. or 24-in. on-center (o.c.) spacing of studs, joists, and rafters. So-called advanced framing, actually developed in the 1970s as optimum value engineering (OVE) framing, uses the minimum amount of lumber consistent with structural strength and stability: studs, joists, and rafters are spaced at 24-in. o.c.; double plates are eliminated, with discontinuities in single plates bridged with metal straps or overlapping, but short, wooden plates; 2 × 6 studs replace 2 × 4 studs; all joists, rafters, and studs align vertically, so that loads find consistent paths down to the foundation; windows and doors are framed with single, rather than double, studs, and so on. The contemporary interest in such optimized framing is driven by energy concerns: all of the wood that has been eliminated from the exterior walls is replaced with insulation, minimizing thermal bridging through the wood. The use of 2 × 6 exterior wall studs increases space for insulation and still results in a net savings of wood, compared with traditional 2 × 4 studs with double plates at 16 in. o.c. Traditional platform framing is illustrated in Figure 3.12, with only the basic structural elements shown. An advanced framing section would appear almost the same, except that single instead of double top plates would be used under the joists. However, many of the "reforms" embodied in advanced framing — including the elimination of numerous studs at corners, doors or windows, and the increased spacing and alignment of studs, joists, and rafters at 24 in. o.c. — do not appear in this type of drawing.

© 2020 Jonathan Ochshorn; all rights reserved. This section first posted November 15, 2020; last updated November 15, 2020.