Lecture notes

Department of Architecture, Cornell University

ARCH 2614/5614 Building Technology I: Materials and Methods

Jonathan Ochshorn

contact | office hours

Movement, joints, and flashing

Building joints and movement

Issues:

- buildings are assembled from pieces

- must be constructable

- must maintain continuity of air, water, and thermal barriers

- must deal with inevitable movement

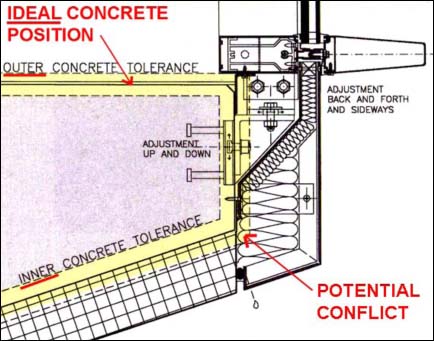

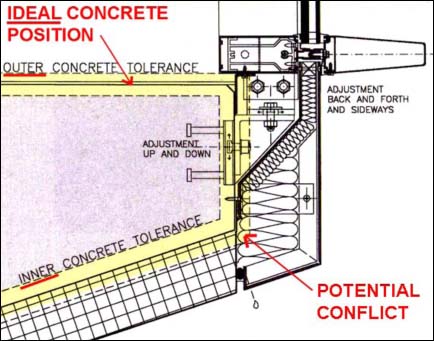

This detail section shows a potential conflict between a cladding panel and a structural concrete slab.

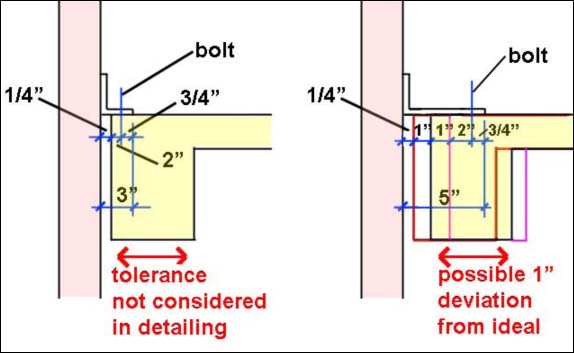

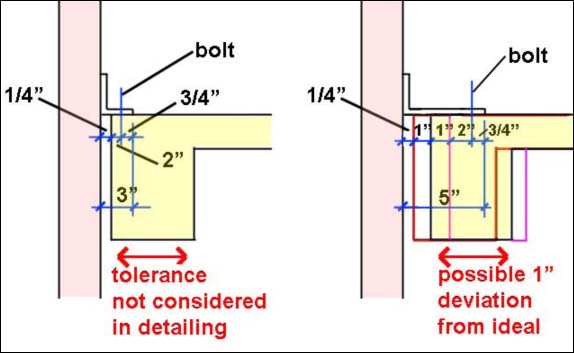

Tolerances: Difference between rough and finished construction. "Rough" construction, in general, refers to the structural frame, which may deviate from it's "ideal" position. "Finished" construction, in general, must be able to be positioned in its exact location, as it is manufactured or constructed with a higher degree of precision. To accommodate the discrepancies between rough and finished construction, details must account for the tolerances of rough construction. The following sketch shows the difference in the dimensions of a clip angle designed for (1) a perfect world; and (2) reality. We assume that the concrete frame has a horizontal tolerance of plus or minus one inch.

Tolerance example assumptions: (1) concrete tolerance is + 1" laterally; (2) bolt spacing is 2" from girder edge and 3/4" from clip angle edge.

Apparent misalignment of concrete foundation pier and steel column, Collegetown Crossing, Ithaca, NY (photo by J. Ochshorn, Oct., 2015)

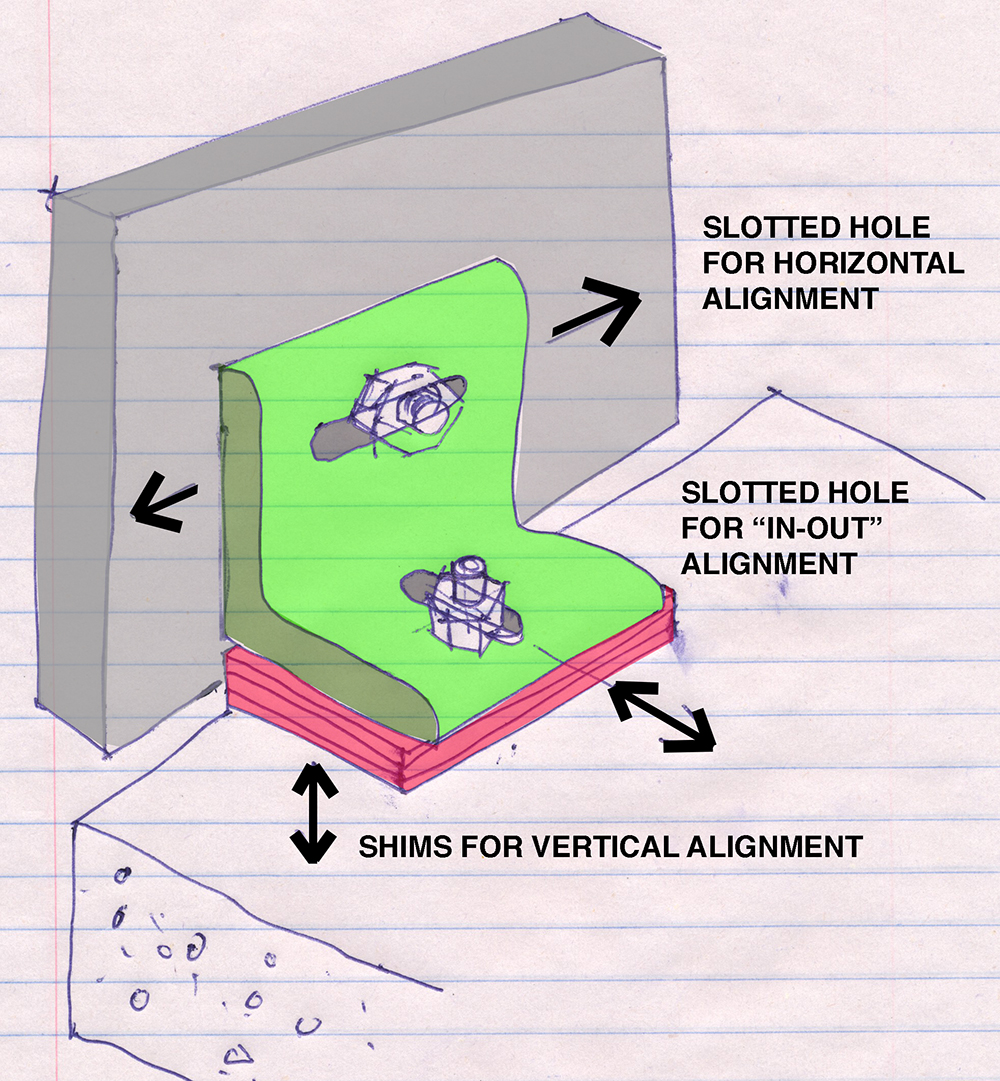

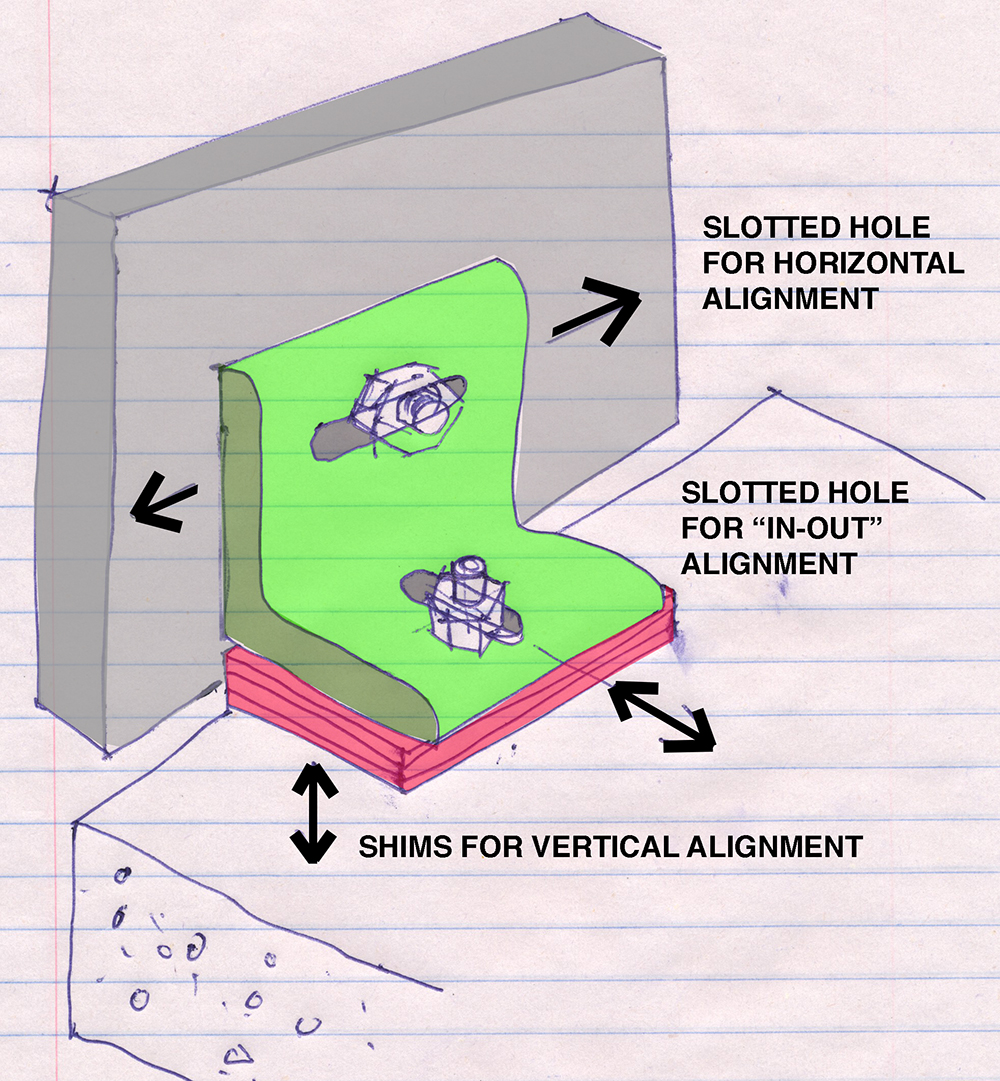

Constructability: In addition to installation clearances to account for constructability and tolerances, it is useful to have connecting strategies or details with 3-way alignment opportunities:

In the sketch above, the clip angle can be adjusted in three orthogonal directions using shims for the vertical direction, and slotted holes in the angle for the two "lateral" or horizontal directions.

Sources for tolerance information

American Concrete Institute (ACI) 117-06 Specifications for Tolerances for Concrete Construction and Materials

Precast/Prestressed Concrete Institute (PCI) Tolerance Manual for Precast and Prestressed Concrete Construction

American Institute of Steel Construction (AISC) 303-05 Code of Standard Practice for Steel Buildings and Bridges

Architectural Woodwork Institute (AWI) Architectural Woodwork Quality Standards

David Ballast The Handbook of Construction Tolerances (latest edition)

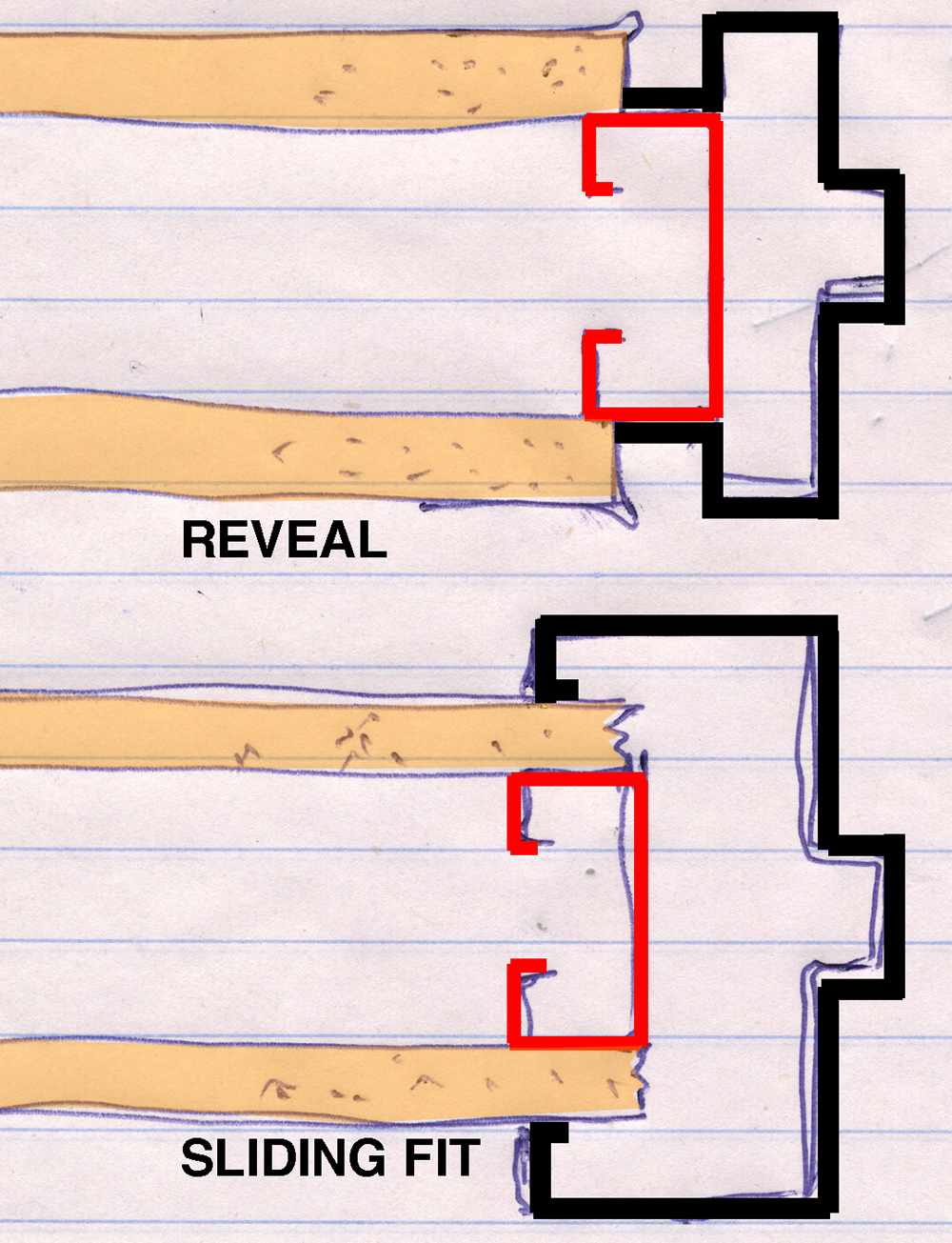

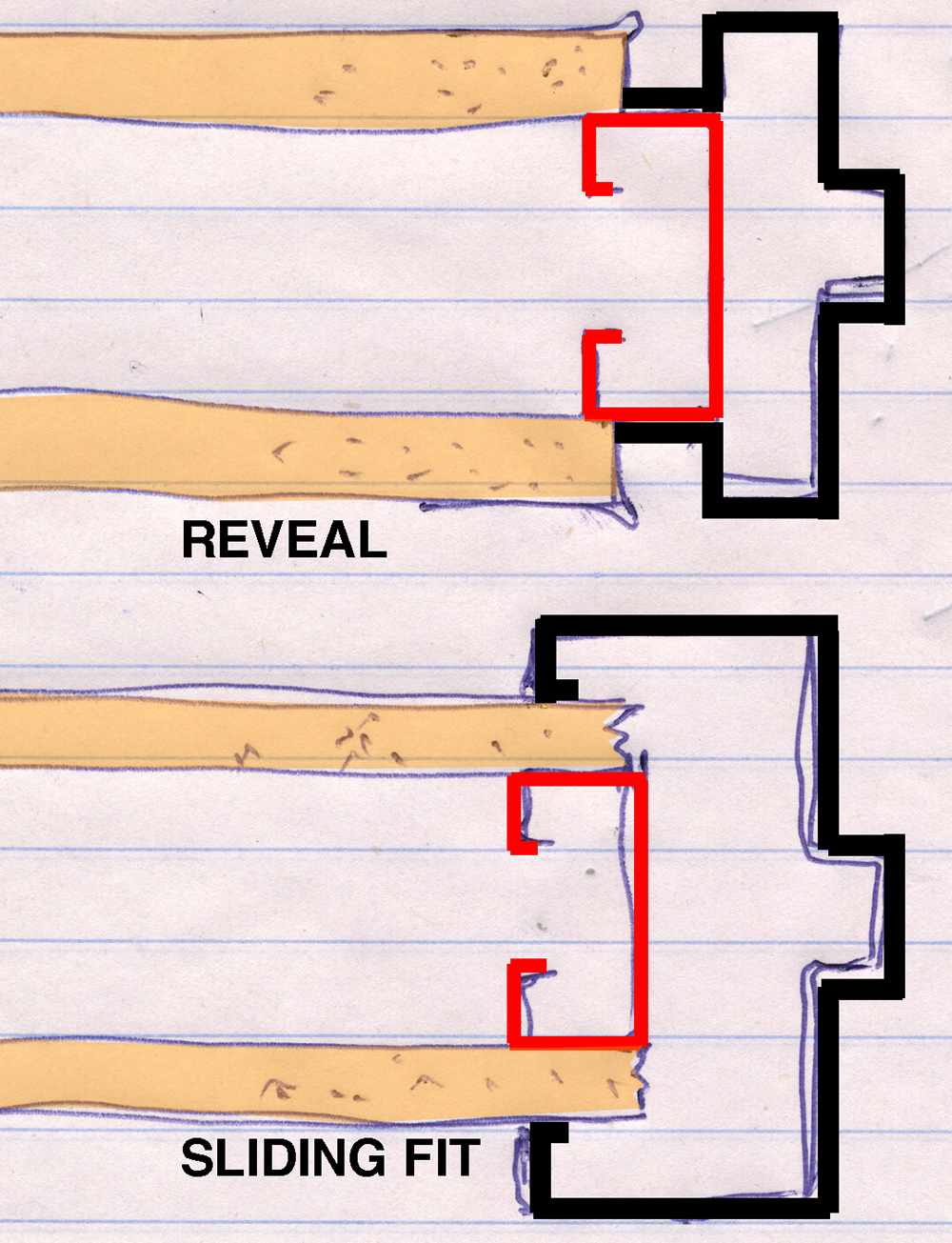

Trim strategies:

sliding fit

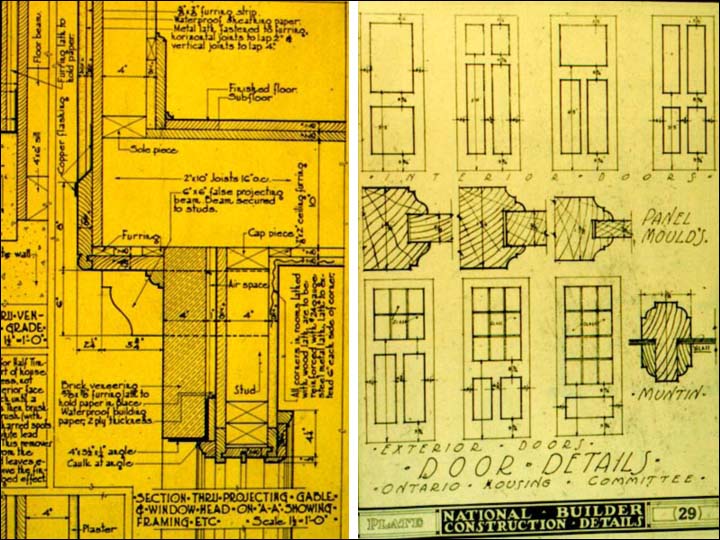

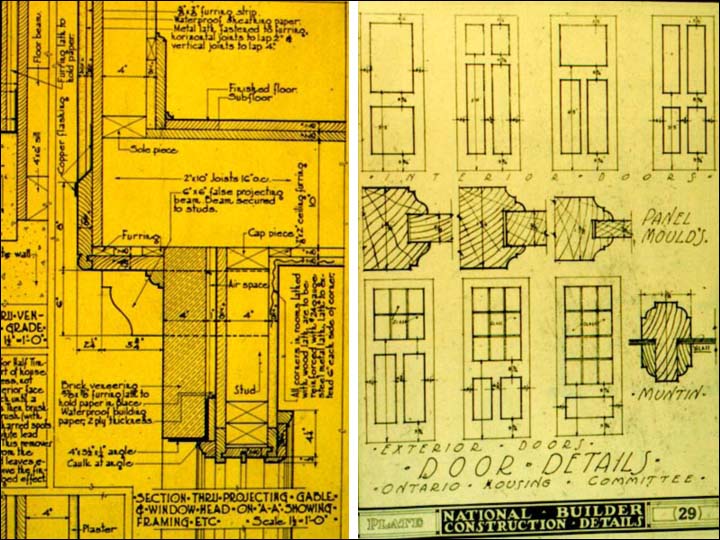

Examples of "sliding fit" strategy with trim and doors from old working drawing manuals.

scribing, filler strips

Video showing traditional scribing techniques as well as proprietary "Euroscriber" device.

video link

"wet" seals (caulks, sealants, tape and spackle, plaster, etc.

Wet seals: sealant joint (left) and spackling of gypsum board/drywall (right)

reveals, shadow lines

Reveal in bathroom cabinet (image source)

Reveals in bathroom wall, Weill Hall (Richard Meier), photo by J. Ochshorn

Two strategies for door frame joints: a reveal (top) and a sliding fit (bottom).

Sources of movement:

- temperature (except for water: expand when heated; contract when cooled)

- moisture (e.g., wood, brick)

- freeze-thaw

- chemical change (e.g., concrete curing results in shrinkage

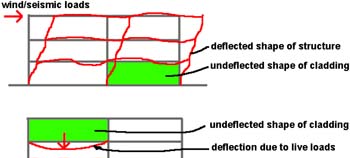

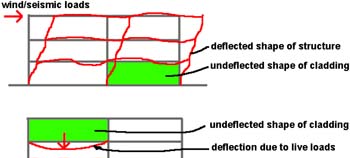

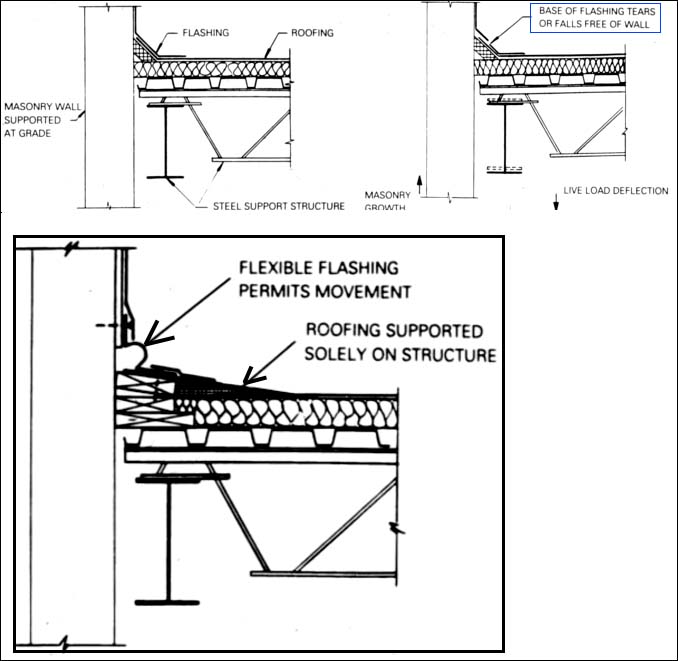

- structural deflection (either large-scale lateral movement due to wind/seismic forces; or more localized deflections caused by live loads)

- differential foundation settlement

- creep (continued deformation beyond that predicted by elastic analysis, in materials such as concrete).

Note increased tendency for movement issues to surface in modern construction because of:

- higher stresses in more slender members (as material strength increases without corresponding increases in stiffness)

- cladding differentiated from insulated structure

- new materials (e.g., plastics) with large movement potential

- larger units with fewer joints

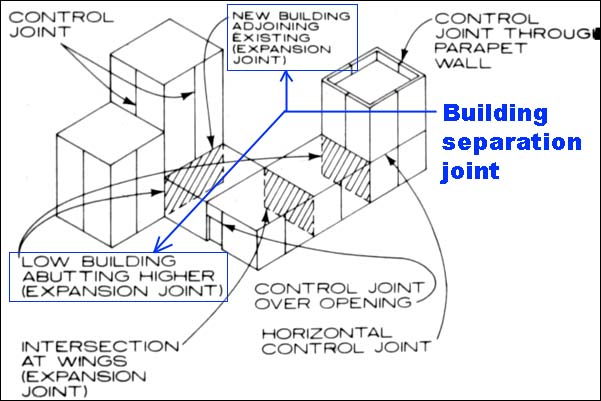

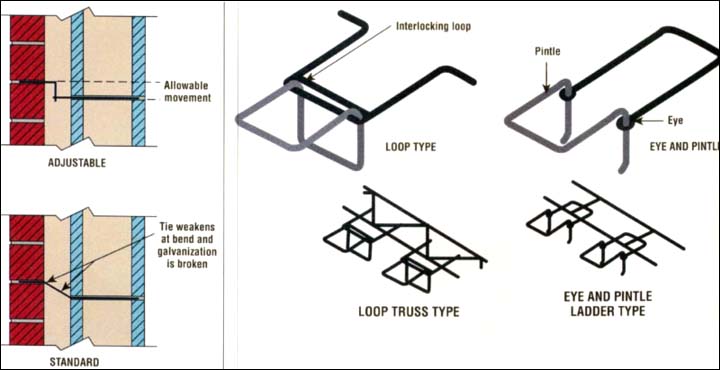

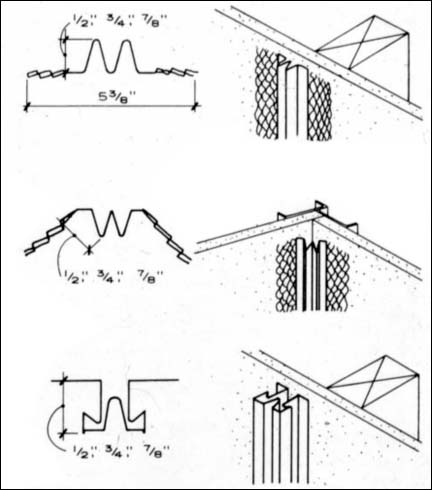

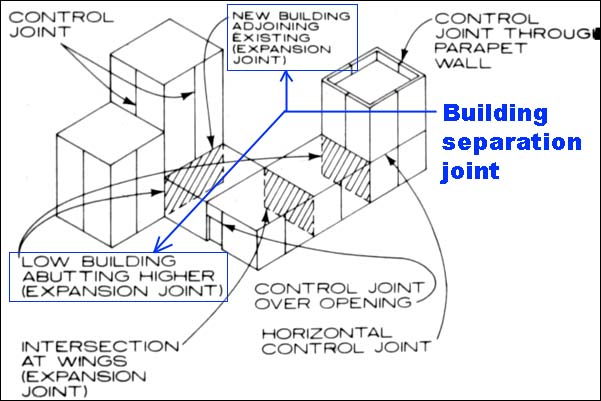

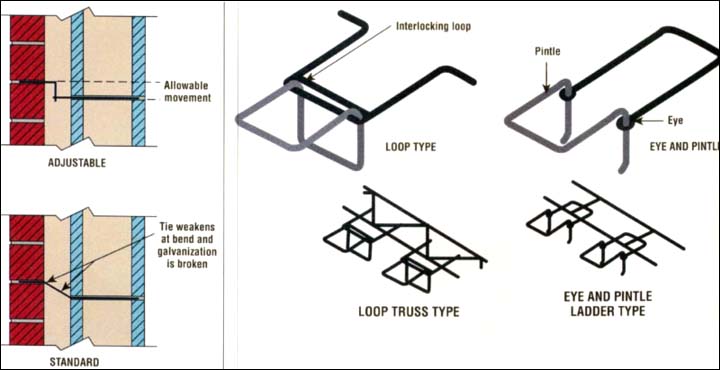

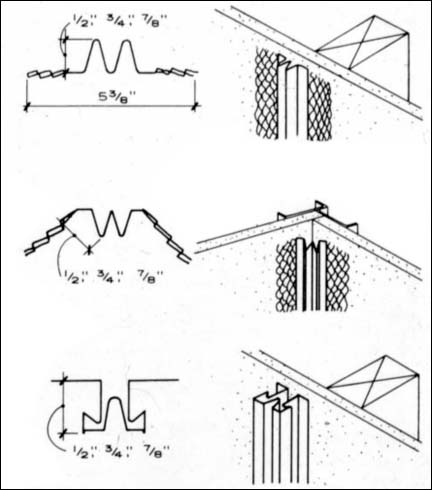

Types of movement joints: Functions of joints vary; inconsistent nomenclature with words like "control joint," "expansion joint," building separation joint."

-

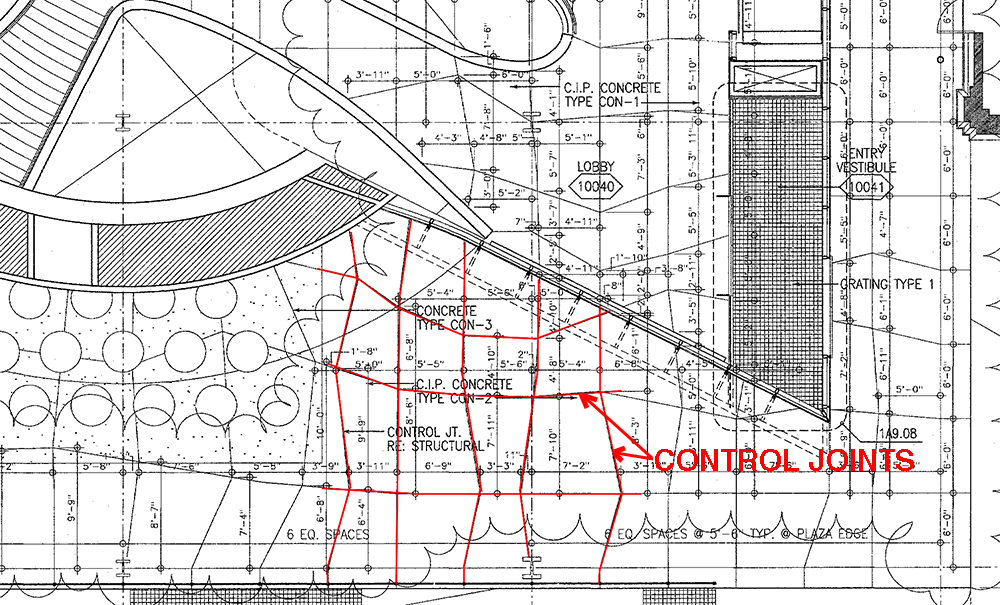

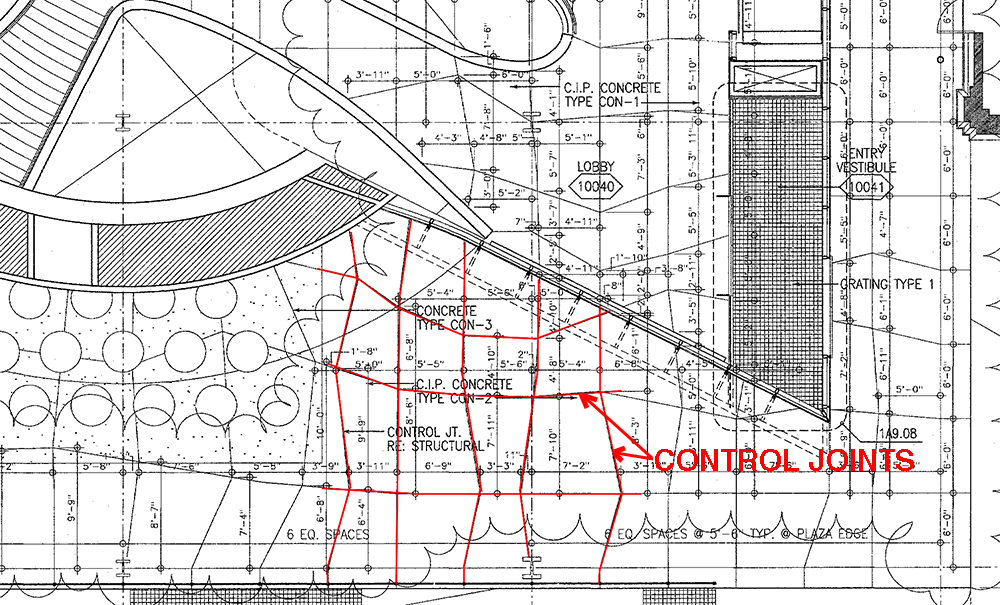

Control joints: used for materials that contract, such as concrete. In a sense, the control joint provides a way to "control" the location of a crack that would have occurred more randomly.

Working drawings specify idiosyncratic control joint location at Milstein Hall, Cornell University.

-

Expansion joints: used for materials that expand, such as brick (when it takes of moisture from the air after having been in the kiln).

Expansion joints separate "panels" of brick, Kennedy-Roberts Hall, Cornell University (see lecture on sealant joints)

-

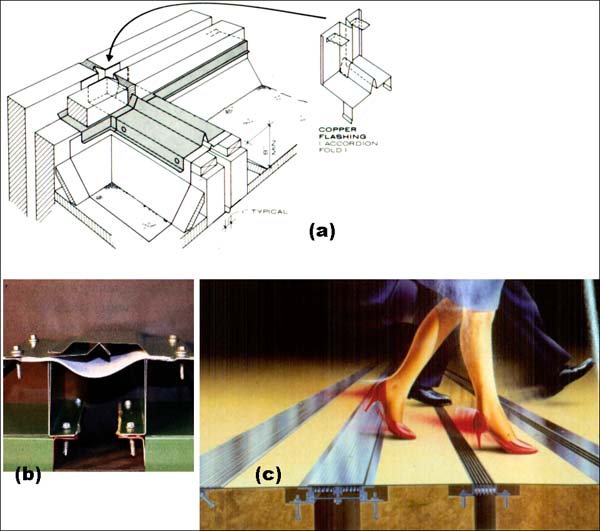

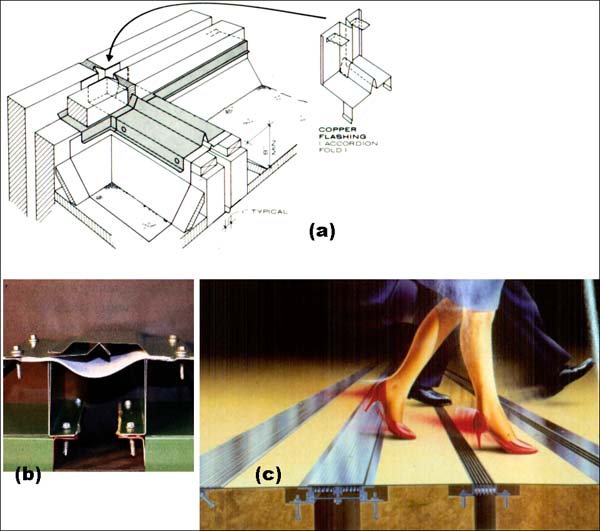

Building separation joints: used to separate parts of the building that would behave differently because of extreme length, or because of abrupt discontinuities in plan or section. These joints are rather extreme, as they literally bisect the building from foundation to roof.

Movement joints in buildings (adapted from Architectural Graphic Standards

Building separation joints ("expansion" joints): from (a) Architectural Graphic Standards; (b) using pre-cured silicone sealant with metal cover plates; and (c) within a floor slab.

Building separation joint in Milstein Hall, Cornell University (photo by J. Ochshorn)

Strategies for dealing with movement:

- prevent (e.g., reinforce or make strong enough to resist movement)

- minimize (anticipate movement and take steps to reduce it, as in insulation of structure)

- accommodate (e.g., use "movement" joints)

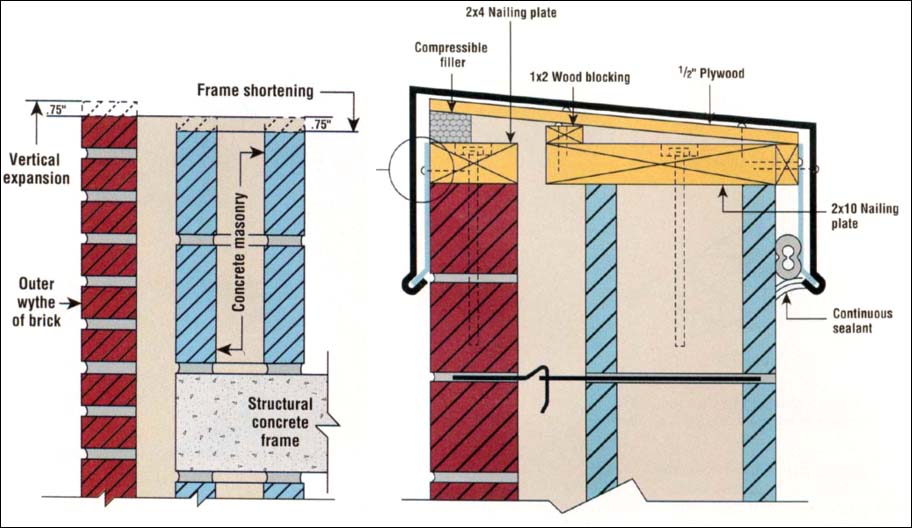

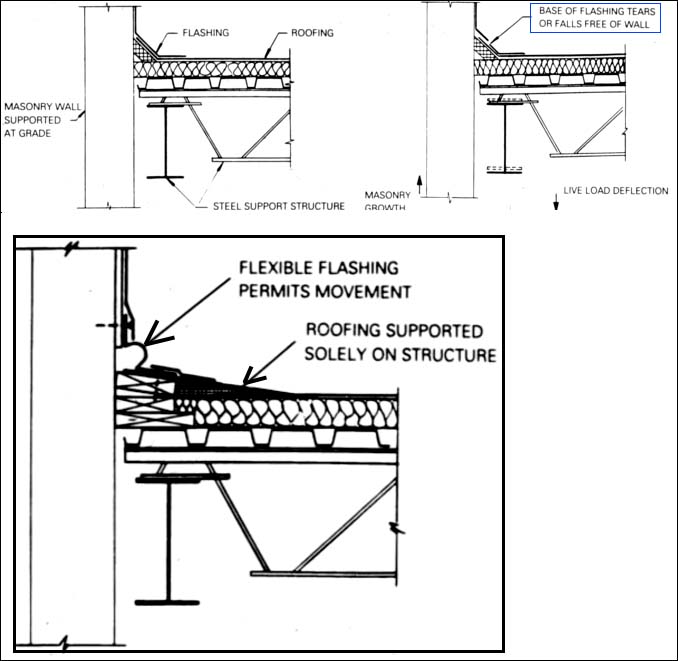

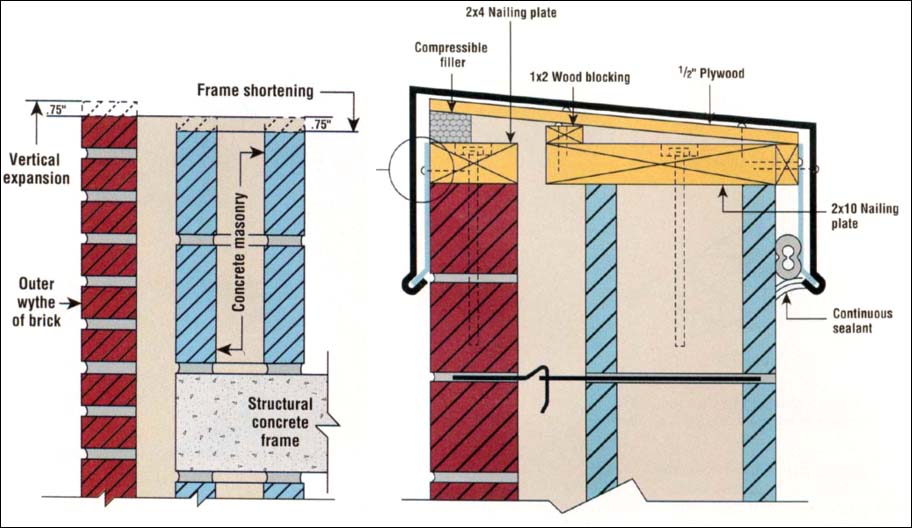

Structural movement relative to cladding:

Examples of accommodation:

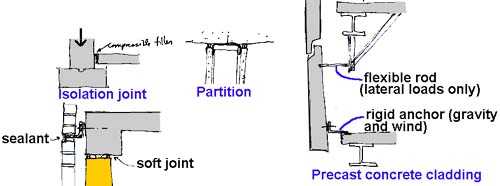

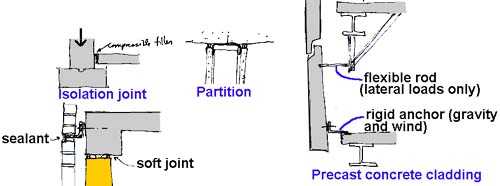

Cladding panels that span between two floors should be supported for vertical (gravity) loads by only one of the floors, with a connection that resists lateral (horizontal) loads only at the other floor. Animation by Jonathan Ochshorn.

Nonstructural elements like partitions should have "soft" joints (right) where they connect with structural elements—typically girders or beams—so that they don't get crushed (left) or, in some cases, transmit unintended loads from an upper level to a lower level (middle). Animation by Jonathan Ochshorn.

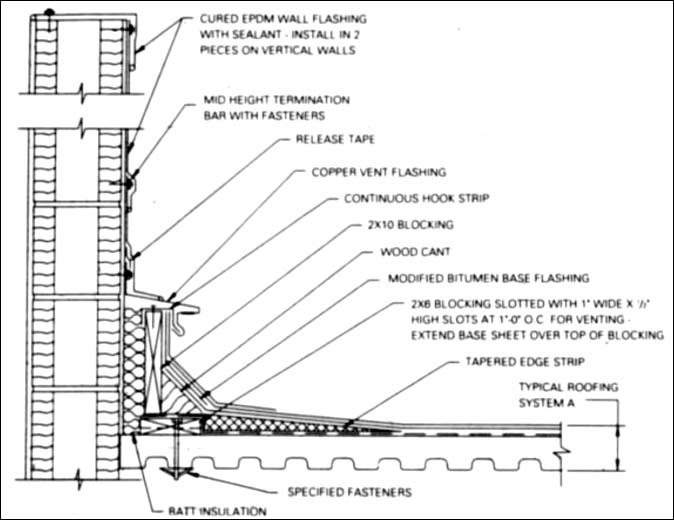

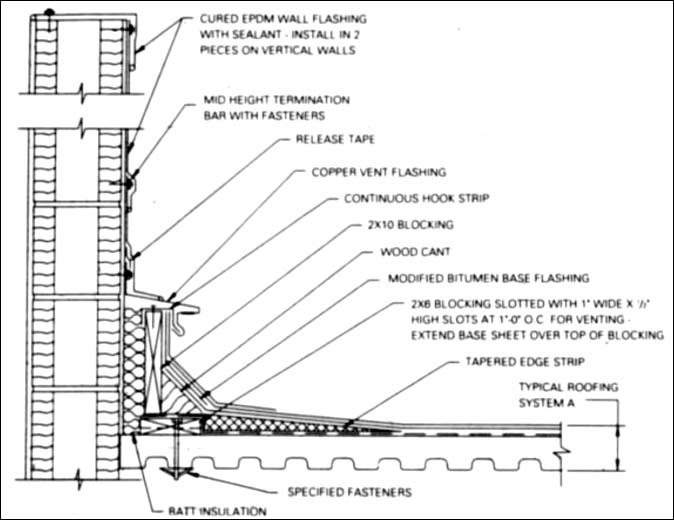

Flashing: Examples given of flashing (metal or "fabric," i.e., rubberized membranes), often used where two materials intersect and water needs to be excluded from the joint. The classic instance is at the intersection of roof and parapet, where flashing traditionally is constructed in two parts that interlock to allow movement.

Flashing at parapet from Architectural Graphic Standards

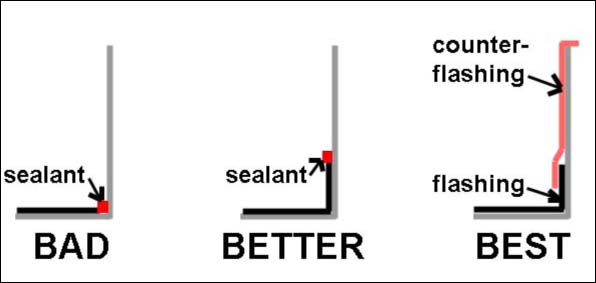

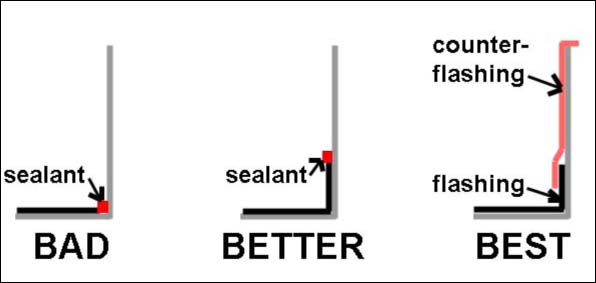

Flashing strategies at parapet: bad, better, and best.

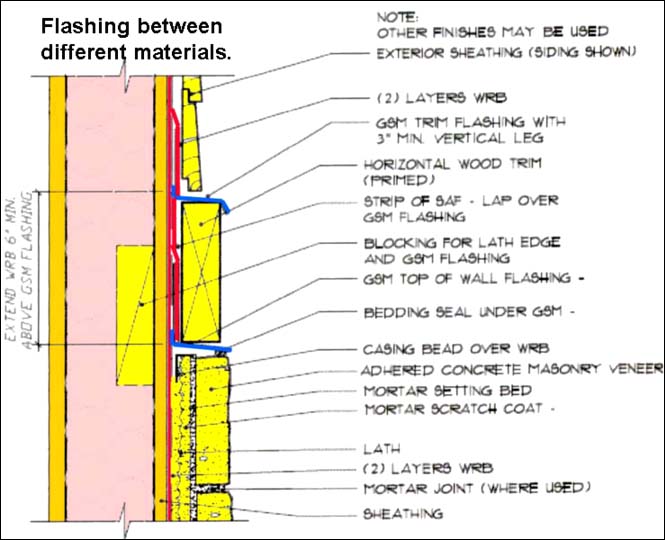

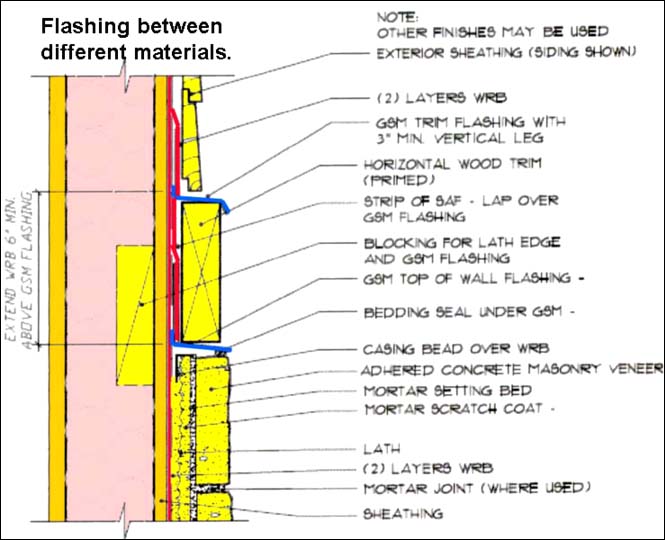

Flashing at dissimilar material intersections.

Flashing must accommodate movement:

Flashing and coping at parapet to accomodate differential expansion and contraction.

Strategy to accomodate movement.

Flashing at parapet to accommodate movement.

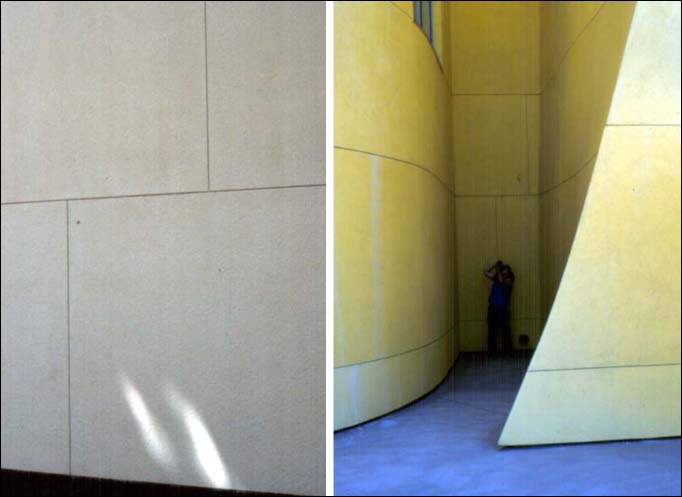

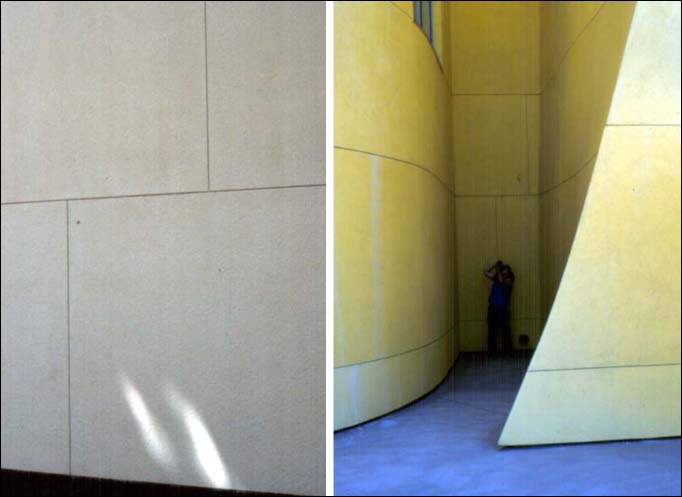

Control joints for materials that shrink (portland cement based).

Control joints to support architectural expression (photos by J. Ochshorn).

Disclaimer: Students are responsible for material presented in class, and required material described on course outline. These notes are provided as a tentative outline of material intended to be presented in lectures only; they may not cover all material, and they may contain information not actually presented. Notes may be updated each year, and may or may not apply to non-current versions of course.

first posted Nov. 2, 2012 | last updated: Oct. 28, 2020

Copyright

2007–2020 J. Ochshorn. All rights reserved. Republishing material on this web site, whether in print or on another web site, in whole or in part, is not permitted without advance permission of the author.