Design-build addition to residence, Ithaca, NY

[Addition homepage]

Weeks 58-60: July 11, 2005 - July 31, 2005

[previous week] |

[next week] |

[week by week index]

After roof deck material finally arrives, Susan and I use the temporary scaffold platform to lift, first 58 pressure-treated 2x4s, and then 76 12'-long "Trex" 5/4 x 6 deck planks to the roof. Of course, all the material is first marked, cut, and drilled so that it can be easily screwed together at the roof level. By using the scaffold, we avoid having to carry all 134 pieces up three flights of stairs in the addition.

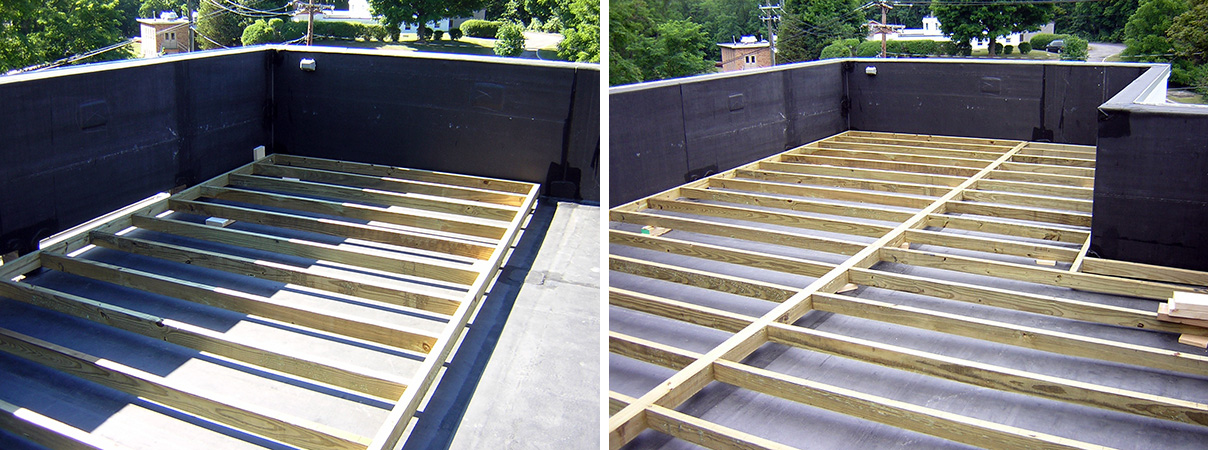

An 8-foot-wide section of 2x4 supports is screwed together first, and then slid into place (left); the next sections are assembled independently, moved into position, and then screwed into the first section (right).

Once assembled and in place, the entire framework is lifted onto temporary shims that are adjusted until the top surface is perfectly level.

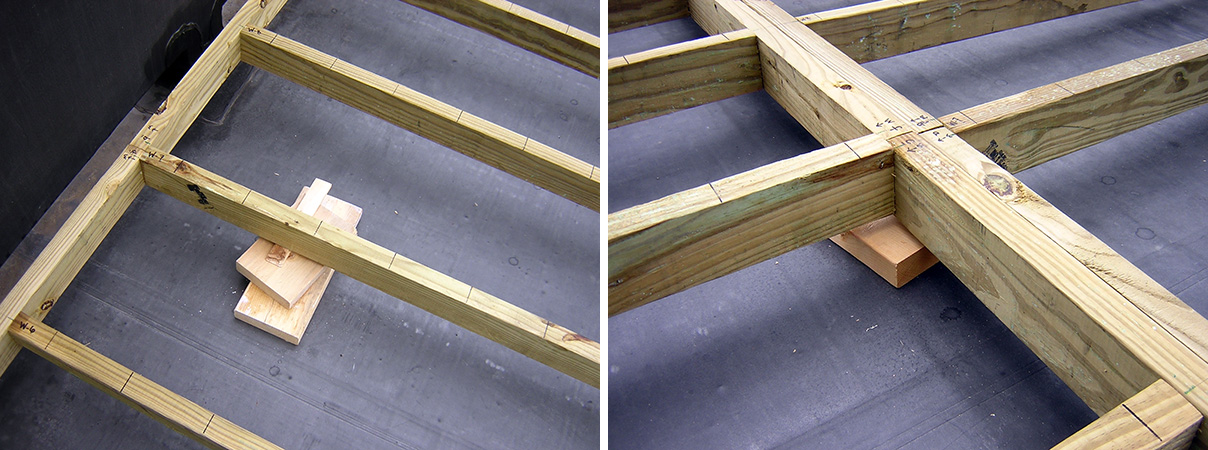

In order to transfer the loads of the finished roof deck to the joists below, 2x8 struts are cut and screwed into each horizontal 2x4 deck support at intervals of about four feet on center. These struts rest on rectangular patches of left-over EPDM ("rubber") membrane to provide extra cushioning for the wooden supports as they bear on the actual roof membrane. To account for deviations in the geometry of the roof surface, the 2x8 struts are not cut exactly to their expected dimension, but are fabricated with a sizable tolerance and fitted in place to the already-leveled 2x4 members (left). After all the 2x8s are in place, their top surfaces are coated with a clear Silicone II flexible sealant to keep water from entering the joint between vertical and horizontal members, and to seal the otherwise exposed cut edges (right).

About half of the 12'-long "Trex" planks are fastened in place full-length, and staggered to avoid the alignment of too many joints (left). The remaining planks are cut to fit the remaining spaces, and screwed into place. Screws holes are pre-drilled at 16" on center, since screwing without pre-drilled holes, while possible, leaves a messier condition on the surface. The deck is finished (right). For the record, and due to my miscalculation, there are actually two more "Trex" pieces that needed to be ordered and that will be installed within a few days of this posting.

The final roof business involves cutting the membrane flashing on the parapet walls to reveal six light fixtures that had been covered up by the roofers last summer. The EPDM membrane is sealed against the cast aluminum fixtures with a black Silicone II sealant, and the covers are screwed into place against a gasket.

[previous week] | [next week] | [week by week index]

last updated: 03 August 2005

Copyright 2004-2005 J. Ochshorn. All rights reserved. Republishing material on this web site, whether in print or on another web site, in whole or in part, is not permitted without advance permission of the author.