Jonathan Ochshorn

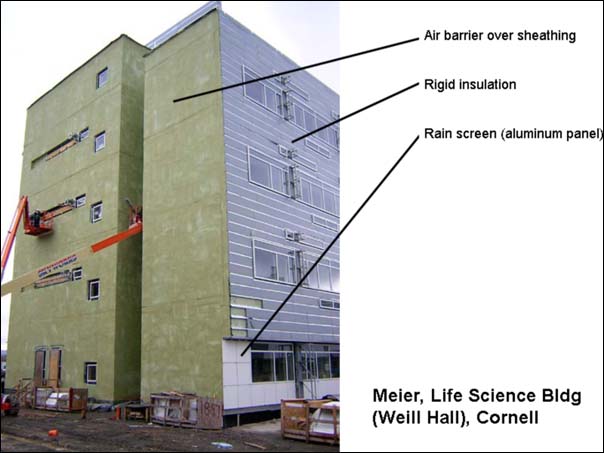

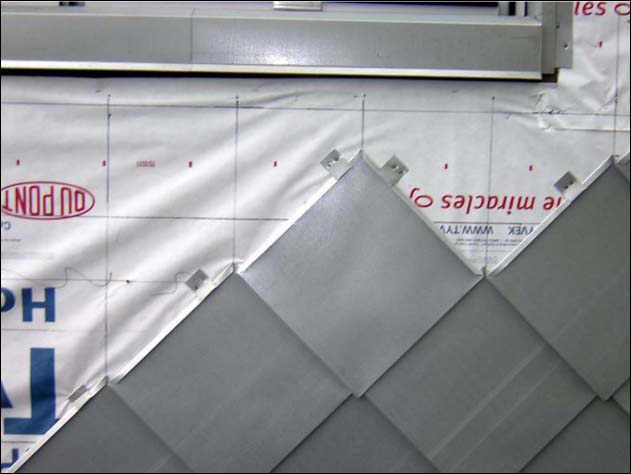

Both precast and metal panels can be used as cladding; metal panels usually are fastened to some kind of back-up system (either metal studs or CMU); whereas precast panels are often attached directly to the structure itself.

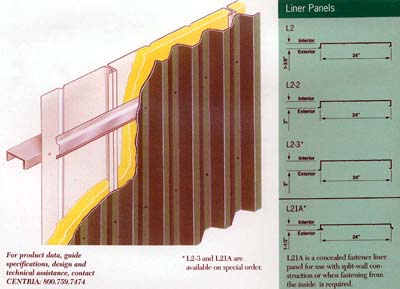

Metal panels used as cladding fall into two main categories:

sheet metal, flat or corrugated, attached to a back-up system; and

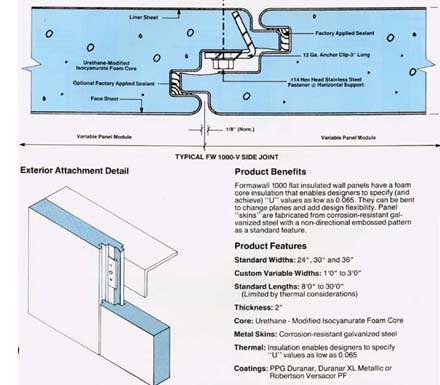

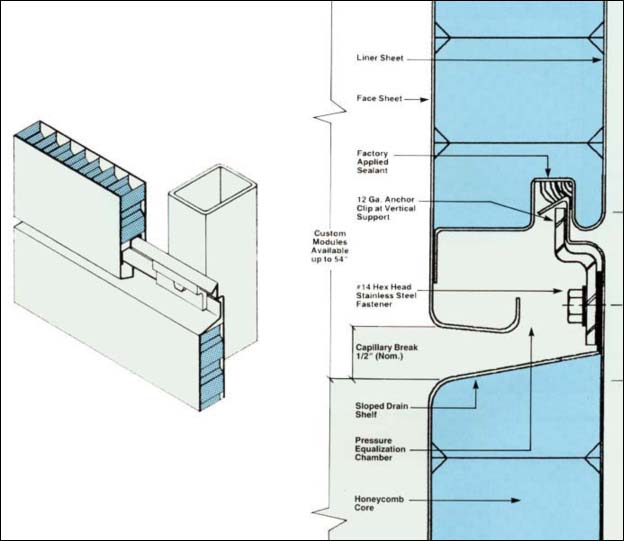

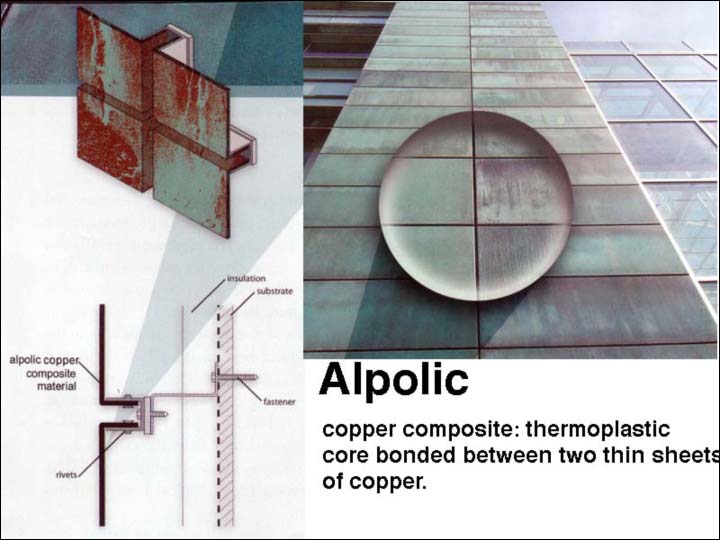

"sandwich" panels consisting of two thinner metal sheets over a rigid core.

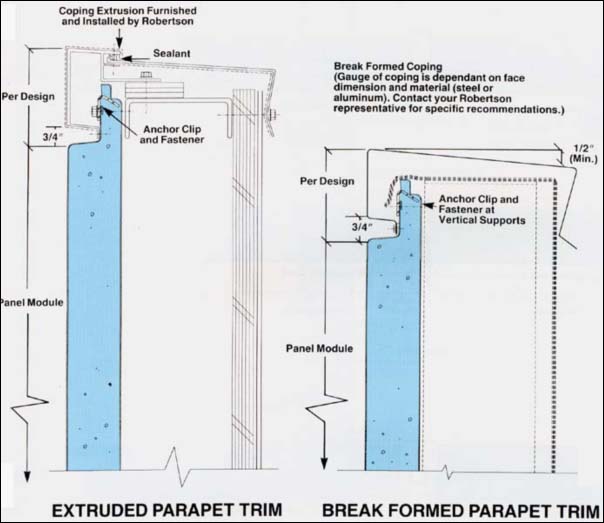

In the latter case, the core can be insulating or not (e.g., foamed plastic versus honeycombed paper). An example of the use of metal panels is shown in the image below (left): Richard Meier's Getty Center (photo by J. Ochshorn); the image at right shows manufacturer's product literature for a proprietary metal panel system. Notice the concealed connection to a back up system (in this case a horizontal angle).

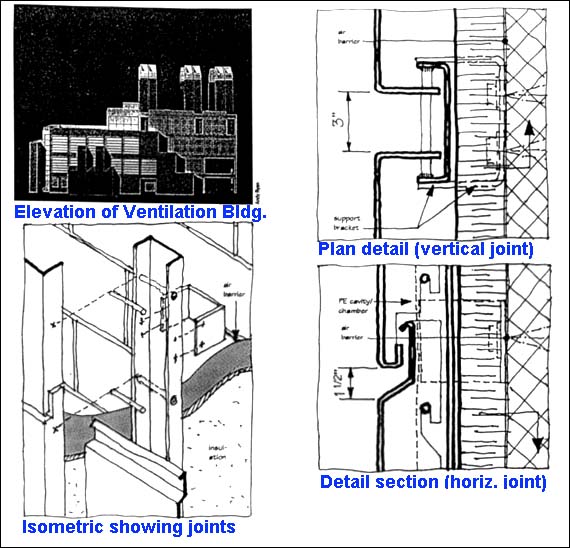

Commercial rain screen metal panel system (over insulated metal panel back-up wall):

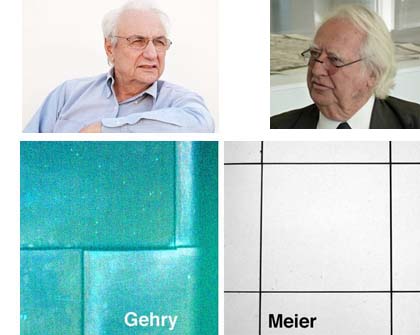

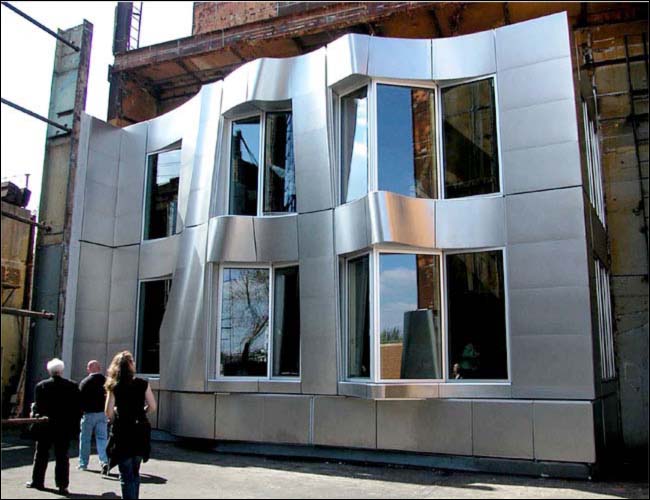

An alternate approach uses sheet metal in a less "formal" manner. Many examples can be found in the work of Frank Gehry, including his project at 340 Main St. in Venice, CA shown below (left). In this case, each panel is just a sheet of metal bent at the edges over the adjacent panels so that the fasteners are hidden, and water is kept out, much like a shingle. The two strategies are contrasted (at right).

Other Cornell metal-clad buildings:

More examples of metal panels

The images below show the overlapping metal panels used at Gehry's Disney Concert Hall in Los Angeles (left), and a detail of their attachment to a metal sub-structure (right). Both photos by J. Ochshorn.

A more "industrial" type of panel is the corrugated variety, shown below. Note that these types of panels have also been appropriated for Architecture (with a capital "A"). See, for example, Gehry's project at 39 Horizon Ave. in Venice, CA (right).

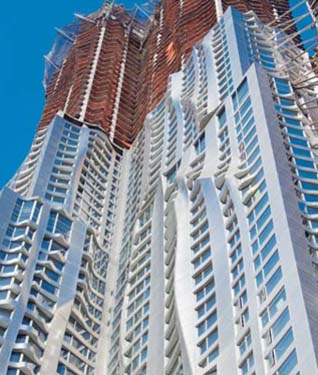

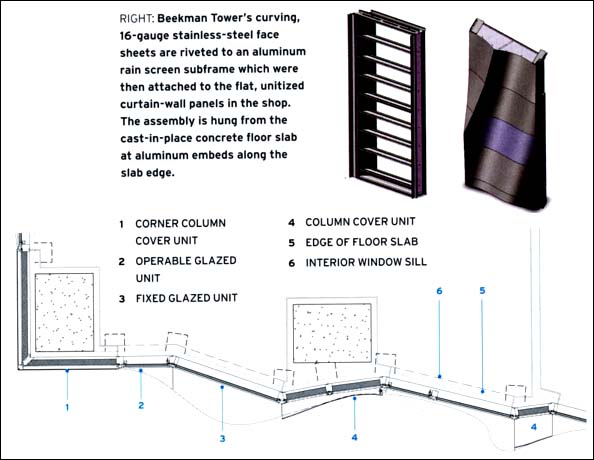

Gehry's Beekman Towers, NYC (2010)

Design process (per AR Sept. 2010):

*A parameter is a variable to which other variables are related, and these other variables can be obtained by means of parametric equations. In this manner, design modifications and creation of a family of parts can be performed in remarkably quick time compared with the redrawing required by traditional CAD.

See: Lstiburek, BSI-098: Great Fire of London

Precast concrete panels can be load bearing or used just as non-load-bearing cladding. The latter use is primarily discussed here. Typical cladding panels are attached directly to the structure, rather than to a back-up wall or sub-structure as is usual for metal panels. An excellent reference is the PCI design handbook: precast and prestressed concrete. Characteristics of precast panels are as follows:

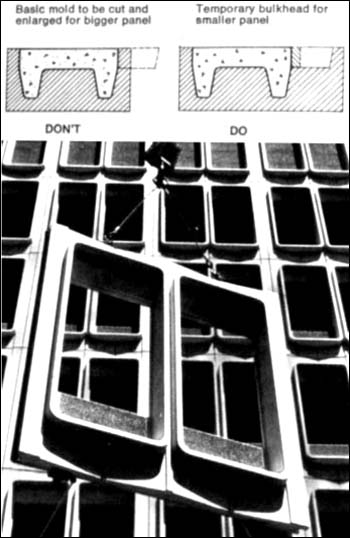

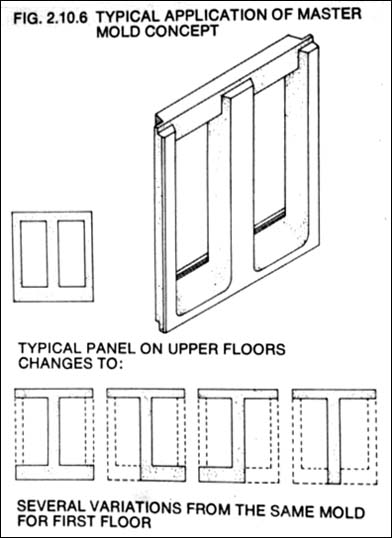

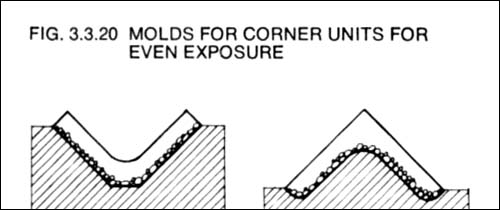

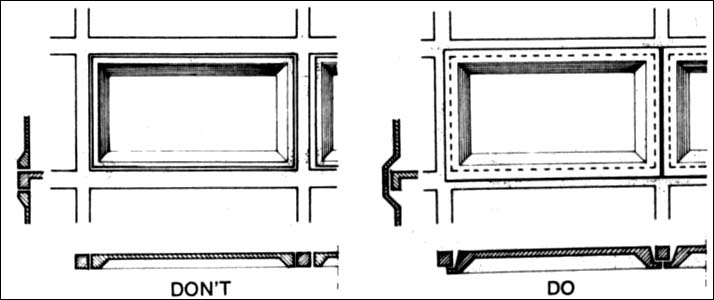

Forms are created in a precast plant. Economy demands the use of repetitive shapes, or shapes that can be made by blocking off areas within a larger, standardized, form.

Panels are typically cast once per day, with special curing processes that accelerate the curing time compared with conventional site-cast concrete. That is, the design strength is almost reached in 24 hours (rather than 28 days).

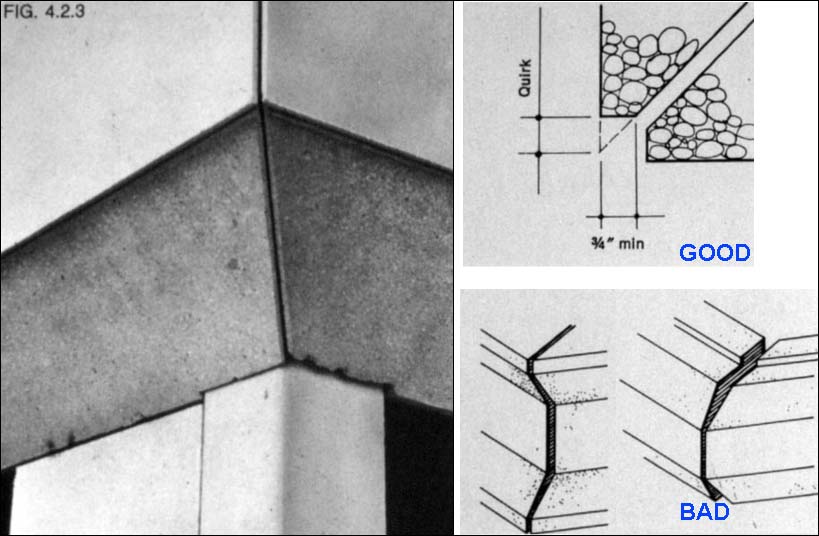

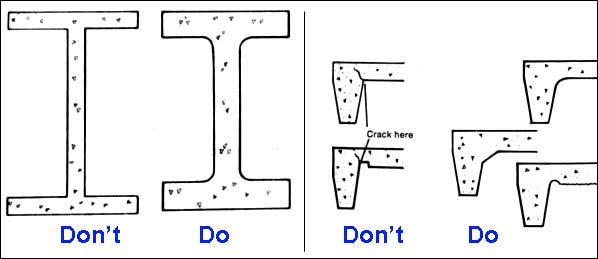

Avoid sharp corners and edges, as these are more easily chipped and cracked.

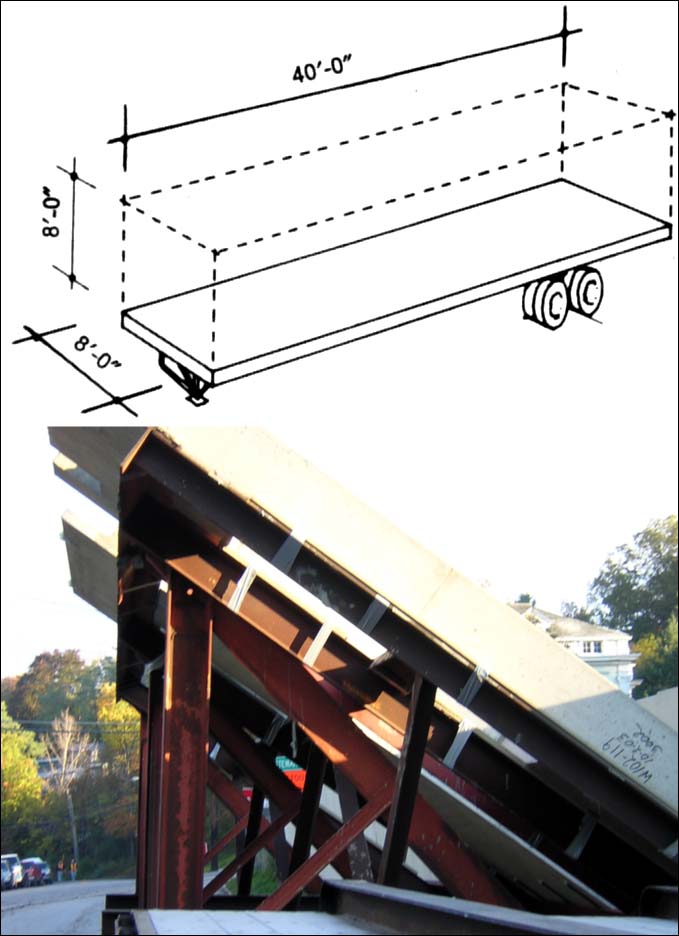

Avoid sharp angles also because they tend to attract stress concentrations, especially under the dynamic loading associated with transportation over bumpy roads.

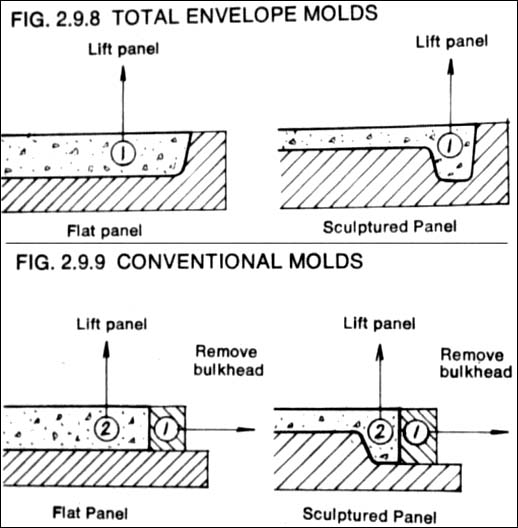

Panels are typically cast horizontally, so the bottom surface is the "good" one, i.e., the one directly in contact with the bottom of the form.

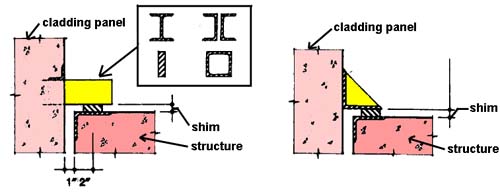

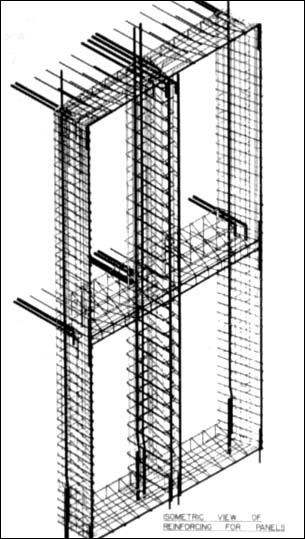

Metal attachments are inserted into the precast concrete, both for erection purposes, and also for attachment to the actual structure. Notice that the actual connection is metal to metal, with a steel insert embedded in the panel, and another in the structural slab.

As an alternative to metal inserts for attachment, it is also possible to leave rebars protruding from the panel which are then inserted into holes or grooves left in the adjacent panels. At the site, such grooves or holes are then filled with grout (concrete), emulating a site-cast condition.

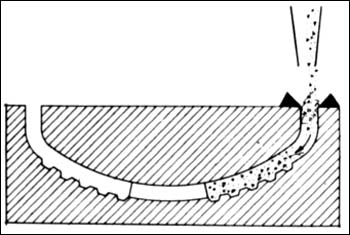

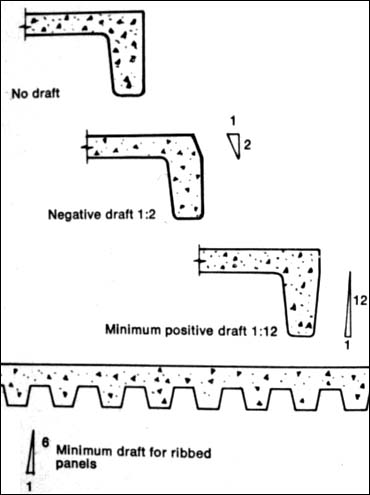

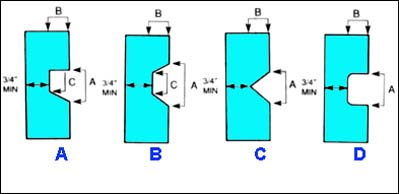

A draft or angled side, is generally required, so that the panels can be easily lifted out of their reusable forms. The minimum positive draft is typically taken as 1:12.

Tolerances need to be considered so that panels can be attached to structures already in place.

And, even though not shown in the "architectural" images here, remember that precast concrete is also, always, reinforced with steel:

An example of a building with precast panels is shown below: Malott Hall at Cornell, designed by Levatich, Miller, Hoffman (photo by J. Ochshorn)

Precast cladding being installed on an East side building in NYC (photo by J. Ochshorn, July 2017)

Tilt-up concrete Tilt-up is a kind of site-cast/precast hybrid, in that wall panels are cast on site, but not in place. Typically, they are cast on a horizontal floor slab, which creates an ideal base for a flat wall panel, and eliminates much of the high cost due to formwork. After curing, the wall panels are then "tilted up" into place. An early tilt-up pioneer was early 20th-century California-based architect Irving Gill. Modern techniques allow for more flexible designs.

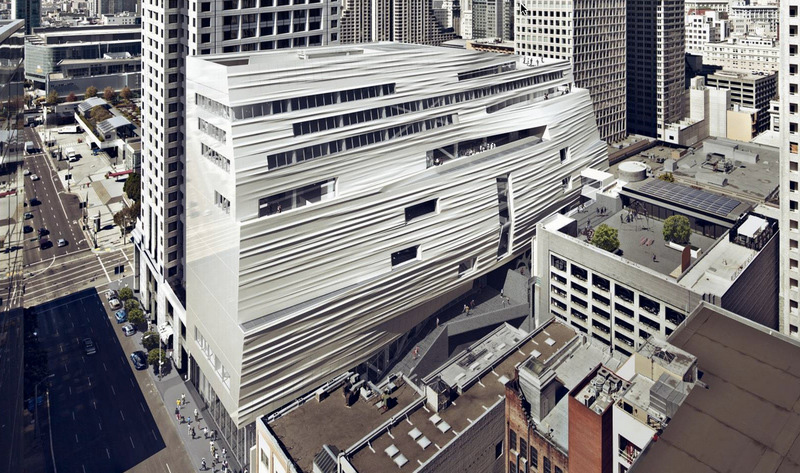

Petroleum-derived polymers, already widely used in non-building applications, have made an appearance as architectural cladding. See this article about the addition to the San Francisco Museum of Modern Art: "Architect Snøhetta designed the building with an unconventional white exterior that includes large bulges and small ripples inspired by the bay and nearby waters. The architect's liberal creativity was made possible by using a facade comprised of a synthetic fiber reinforced polymer (FRP) composite with added natural aggregates. The material, uniquely formulated by fabricator Kreysler and Associates, can be molded in an infinite amount of shapes and is considerably more cost effective and lightweight compared to traditional materials. Kreysler and Associates is molding the fire resistant material into 700 unique panels approximately 3/16th of an inch thick. Each panel will be fastened to an exterior aluminum frame and when completed will represent the largest installation ever of an FRP. Deliveries and installation of the panels are slated to start later this year [2014]."

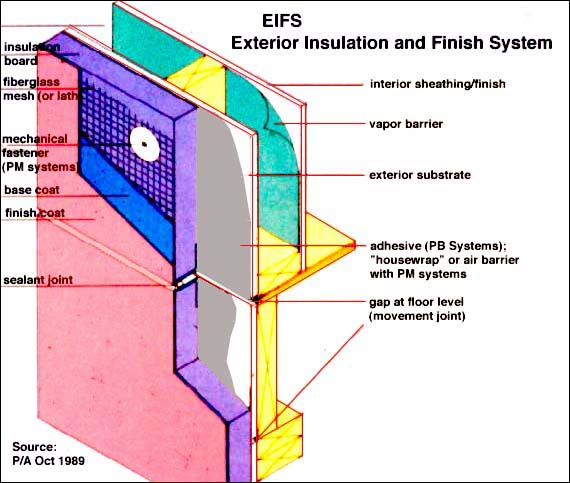

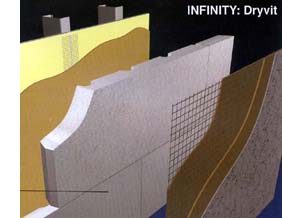

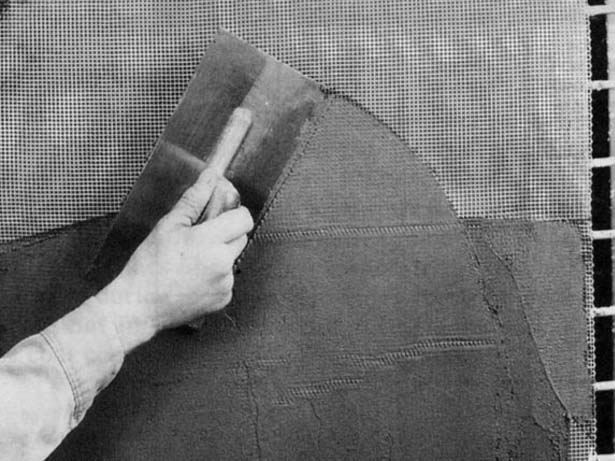

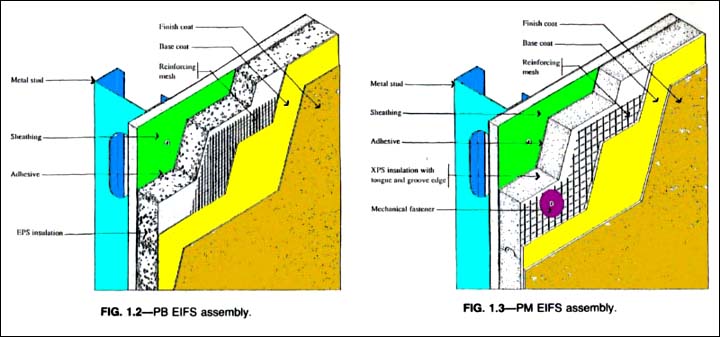

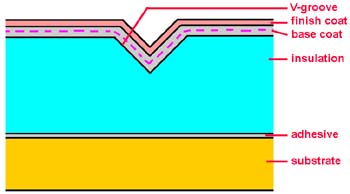

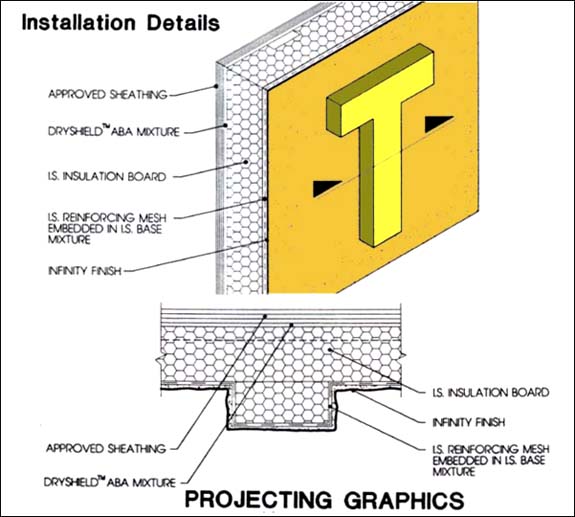

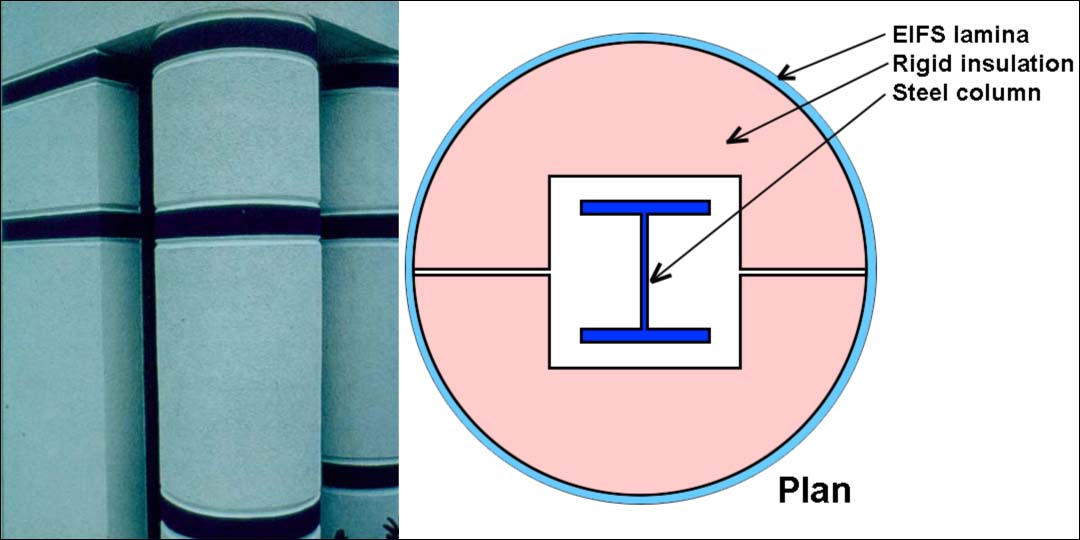

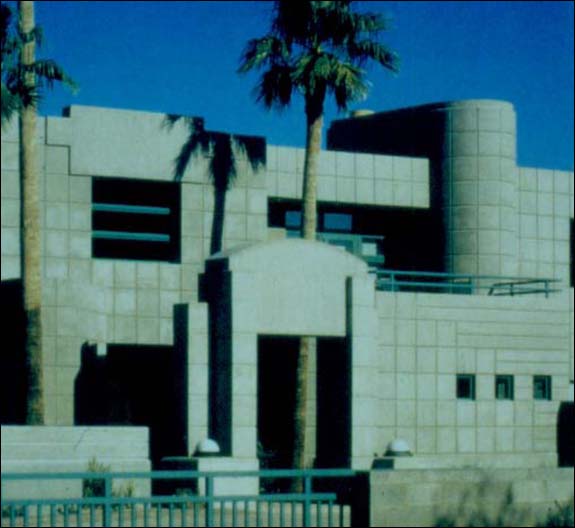

EIFS (pronounced eef-us), stands for Exterior Insulation and Finish System and consists of cementitious lamina applied over insulation, thereby solving the problems of insulation and cladding within one thermally-efficient and inexpensive system. The EIFS is applied over a substrate which can be virtually any assembly that provides a flat surface onto which the EIFS is adhered or mechanically attached. EIFS is a classic "barrier" system without a second line of defense, although various proprietary "rain-screen" variations are marketed (including the one pictured in the image below, at right).

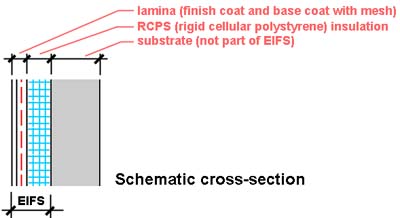

The images below show a schematic cross-section through EIFS (left) and an advertisement for a proprietary EIFS product (right) showing the same layers.

Virtually anything can be a substrate for EIFS, including existing cladding systems. Examples include:

In the image below (Stewart Avenue, Ithaca, NY), insulation boards are being mechanically fastened to an existing CMU wall (photo by J. Ochshorn):

PB: polymer-based

PM: polymer-modified

MB: mineral-based (i.e., not EIFS)

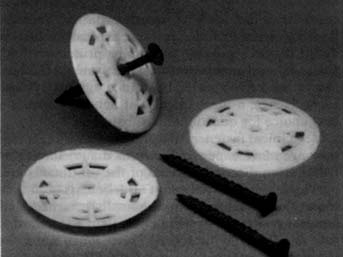

The image below shows a large plastic washer, used where the insulation boards are mechanically fastened to the substrate with long screws (which would otherwise punch through the soft insulation board).

Two primary insulation types are used, corresponding to the two EIFS system types (both are Rigid Cellular Polystyrene, or RCPS):

EPS: (molded) Expanded Polystyrene

XPS: Extruded (expanded) Polystyrene

Comparison

Aesthetic reveals

Using a hot groover (left), lines, with various profiles, can be "drawn" on the surface of the EIFS, as shown in section (right) with a "V-groove;" an application of such aesthetic lines is shown on College Avenue, Ithaca, NY (photo by J. Ochshorn)

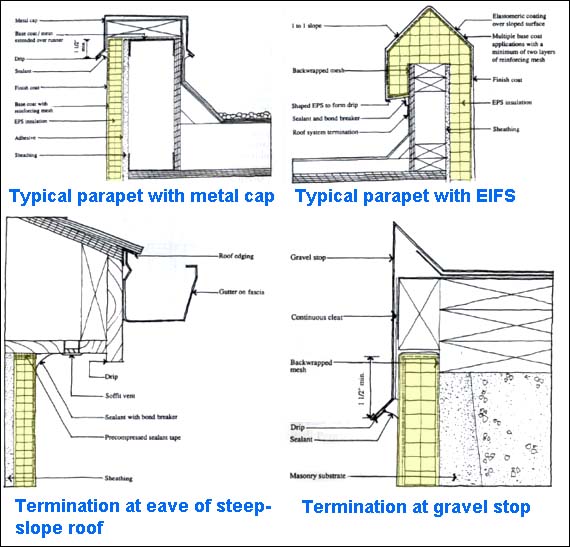

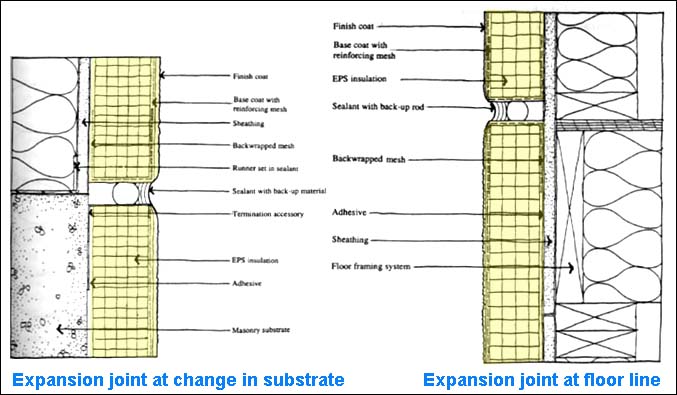

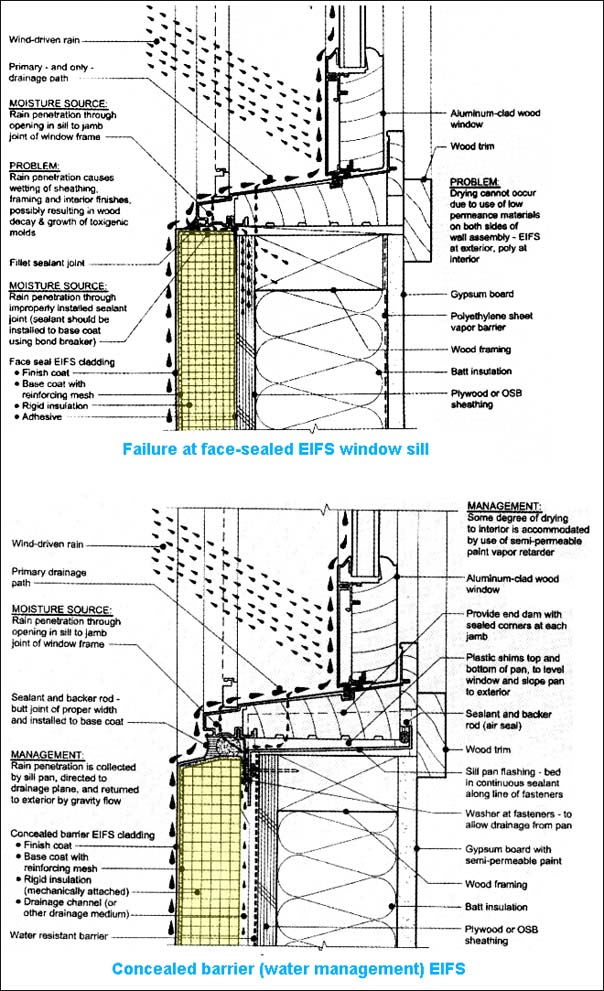

Numerous problems were experienced, especially in residential contexts, with EIFS, mostly because of inadequate attention to detailing at penetrations and terminations (e.g., windows and doors, or intersections with other materials). A few points should be observed:

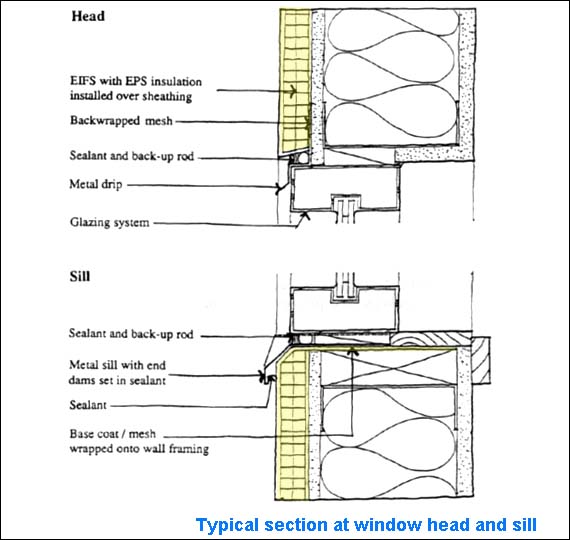

Detailing recommendations:

Another issue with EIFS is impact resistance. The system can be made more impact resistant by using XPS insulation board (and PM EIFS); and by increasing the gauge of the fiberglass mesh in the base coat.

A final issue with EIFS is that of its "moral" standing within the "discourse" of modernism. The following quote from "Curtains for the Wall," an unpublished paper by David Glasser (1989 ACSA Technology Conference) implicitly criticizes the system for being too "universal," and for having no real technological constraints that inform its appearance: "The objective of creating a union between the conceptual and instrumental realms of architecture is one of our most cherished professional aspirations..."

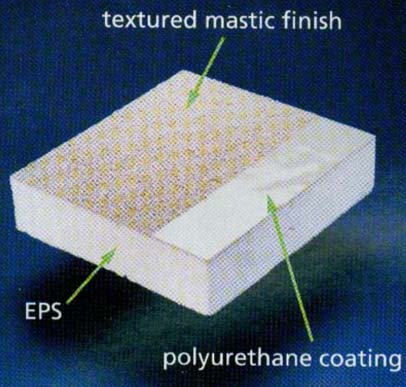

A similar, but even thinner insulation-based cladding system can be manufactured using EPS boards (see above) coated with a thin layer of polyurethane and a thin, textured, mastic finish:

Disclaimer: Students are responsible for material presented in class, and required material described on course outline. These notes are provided as a tentative outline of material intended to be presented in lectures only; they may not cover all material, and they may contain information not actually presented. Notes may be updated each year, and may or may not apply to non-current versions of course.

first posted Oct. 24, 2012 | last updated: Jan. 4, 2023

Copyright

2007–2018 J. Ochshorn. All rights reserved. Republishing material on this web site, whether in print or on another web site, in whole or in part, is not permitted without advance permission of the author.