Jonathan Ochshorn

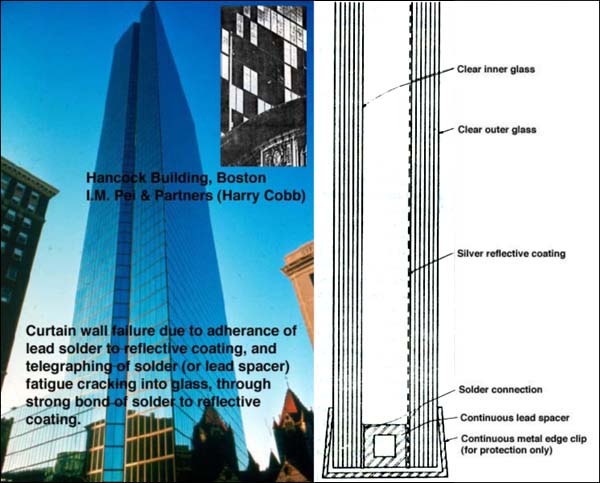

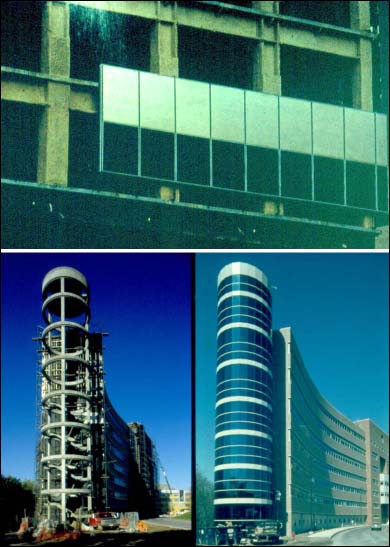

"Curtain wall" refers to any cladding system that is "hung" from the structural frame. See my curtain wall essay for more details. On the other hand, it is most often associated with gridded systems of metal mullions and rails (mostly aluminum) and glass.

Glass "lites" as big as 3' x 4' were produced during classical Roman times; the 10th century production of glass was centered in Murano, Italy, and was based on the creation of flat panes from cylinders or spheres (the latter producing "crown" glass). By the 17th century, glass was "cast" in the form of plate glass, especially for fine mirrors, but this process required much grinding and polishing, and was not particularly economical. Joseph Paxton's Crystal Palace in London (1851) actually used a high-tech (for its time) version of the cylinder process.

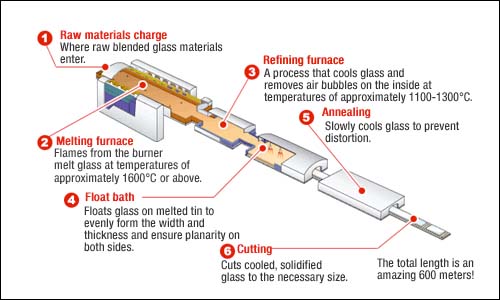

Modern glazing had it's start only in 1959 with the invention of the "float" glass process by Pilkington. Float glass is "cast" in a continuous manufacturing process onto a bed of molten tin, creating smooth surfaces that do not need further treatment. Such glass is annealed (slowly cooled), and is the primary glass product used in building.

Glass consists of SiO2 (silicon dioxide) + soda ash, lime, alumina, and potassium oxide. The primary ingredient, sand, is readily available. Glass is, according to legend, not a solid, but rather a "super-cooled liquid" with an open noncrystaline microstructure. Actually, it is neither a liquid — supercooled or otherwise — nor a solid. It is an amorphous solid — a state somewhere between those two states of matter. And yet glass's liquid-like properties are not enough to explain thicker-bottomed windows, because glass atoms move too slowly for any changes to be visible.

Glass comes in traditionally-defined thicknesses as follows:

Ordinary float glass is "annealed" (slowly cooled)

Tempered glass starts off as ordinary annealed glass, but is reheated to 1200 degrees F, then cooled rapidly to introduce — on purpose — residual stresses that bring the surfaces into compression. This makes the glass stronger (4x as strong as ordinary annealed glass) because the induced compression prevents brittle tensile fracture, the "achilles heel" of ordinary glass. Note that tempered glass must be cut before it is tempered, since once tempered, it cannot be modified.

Tempered glass, if broken, will shatter into small, smooth fragments, so it is actually safer than ordinary glass, which will break into larger, sharper pieces (shards). It is therefore often specified for "safety glazing" applications.

Heat-strengthened glass is similar to tempered glass, but is not reheated to the same extent. It is about 2x stronger than ordinary annealed glass, and is useful in situations where the glazing is subject to thermal stresses.

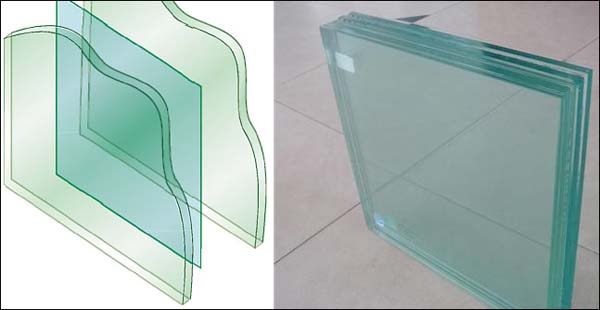

Laminated glass consists of two or more layers of glass (often just annealed glass) with a vinyl interlayer between. This interlayer adheres to the glazing, so that if fractured, the glass "sticks" to the interlayer, and doesn't fall apart as a sharp, dangerous fragment. With multiple layers, such glass can be used in security applications (bullet-proof, blast resistant), or as safety glass.

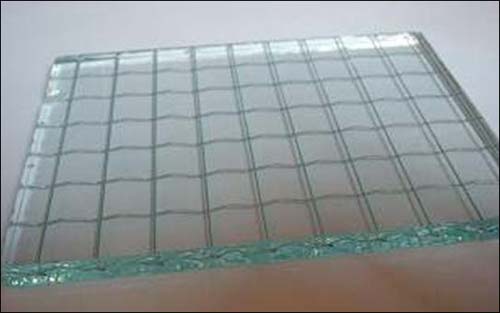

Wired glass is used in applications like fire doors. The wire grid, cast into the glass during the manufacturing process, holds the glass in place even after it may crack when exposed to high heat. Wired glass is a form of rolled glass.

Spandrel glass is just ordinary glass with an opaque coating on the protected side. It is used in curtain walls to hide the structural and mechanical stuff that would otherwise be visible between floors.

Answer — in hazardous locations, defined as follows (without all the fine print):

See Brian Stephens, Window and Storefront thermal Performance, Construction Specifier, Nov. 2013 (click on "read more" to access the article).

Some other definitions that describe the light and heat transmitting properties of glass are as follows:

| Type of glass | Visible light transmission (VLT) | Solar heat gain coefficient (SHGC) | Winter Night U-value | Light-to-solar gain (LSG) ratio |

|---|---|---|---|---|

| Dual-pane tiinted glass (blue-green) | 69% | 0.49 | 0.47 | 1.41 |

| Double-silver MSVD solar-control low-e glass (clear) | 70% | 0.38 | 0.29 | 1.84 |

| Tinted MSVD solar-control low-e glass (blue-green) | 51% | 0.31 | 0.29 | 1.66 |

| Passive low-e with spectrally selective tinted glass (blue green) | 64% | 0.45 | 0.35 | 1.42 |

| Triple-silver MSVD solar-control low-e lass (clear) | 62% | 0.27 | 0.29 | 2.30 |

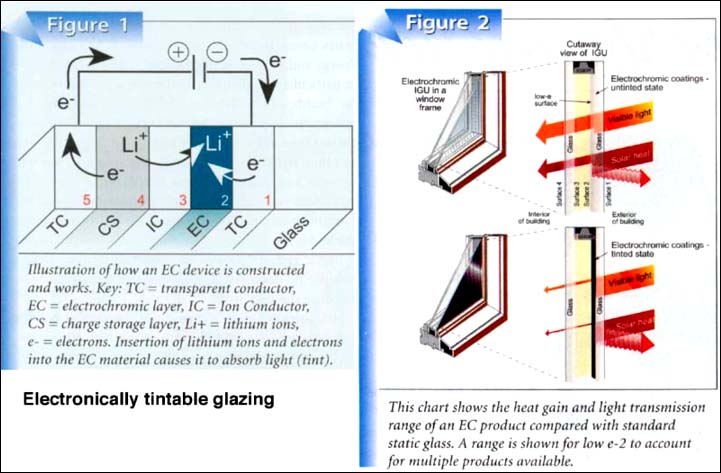

Definitions that describe advanced glass characteristics:

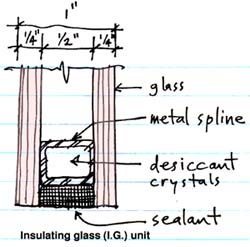

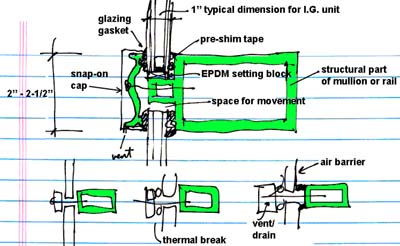

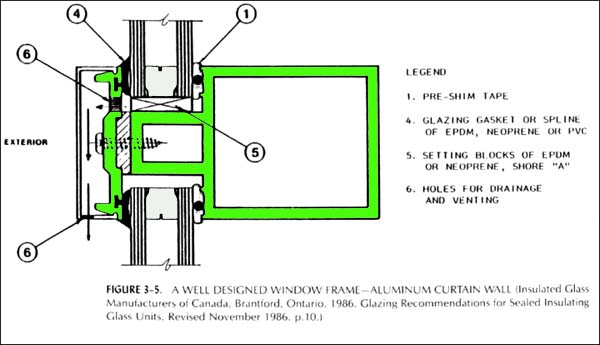

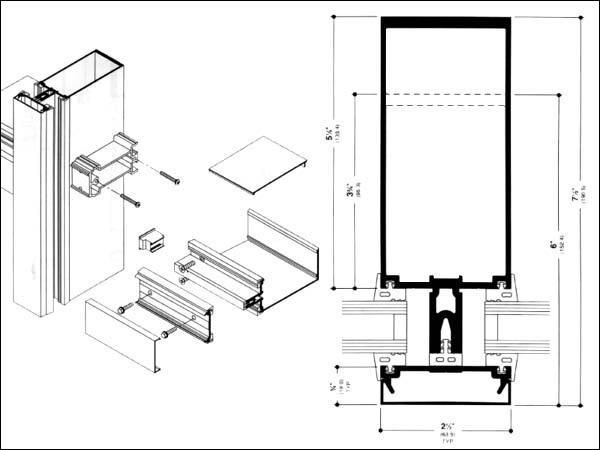

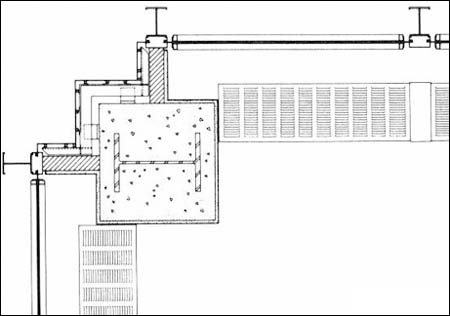

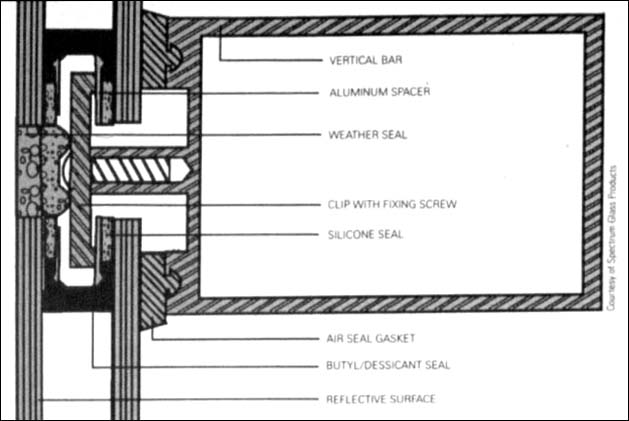

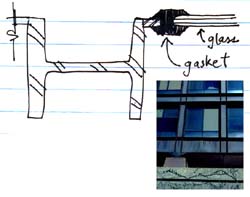

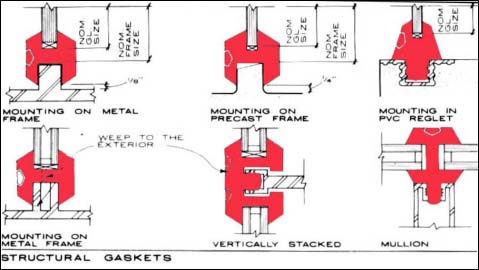

Most curtain wall systems consist of vertical mullions which span from slab to slab, and horizontal rails which span from mullion to mullion. Within the grid thus created, glass panels are inserted, although other materials can also be used within such a grid (especially at the "spandrel" condition). The typical mullion or rail section has the following characteristics:

The mullions and rails are typically extruded aluminum sections.

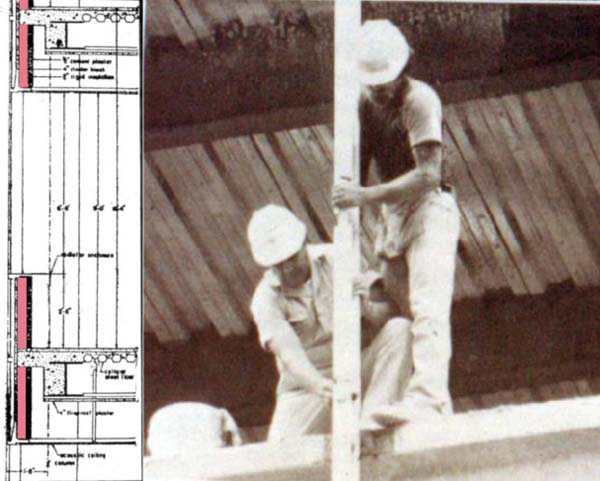

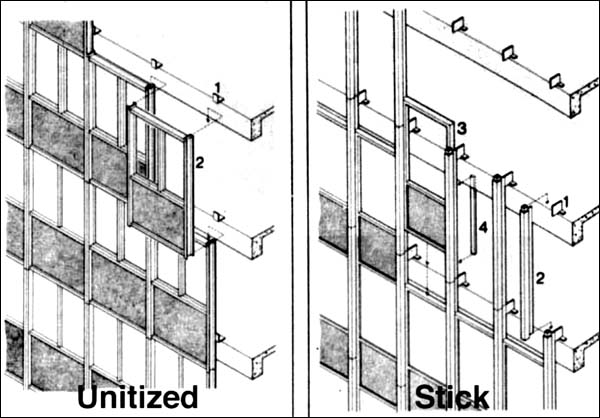

When assembled on site, they are known as "stick construction;" when pre-assembled into rectangular panels, they are known as "unitized construction."

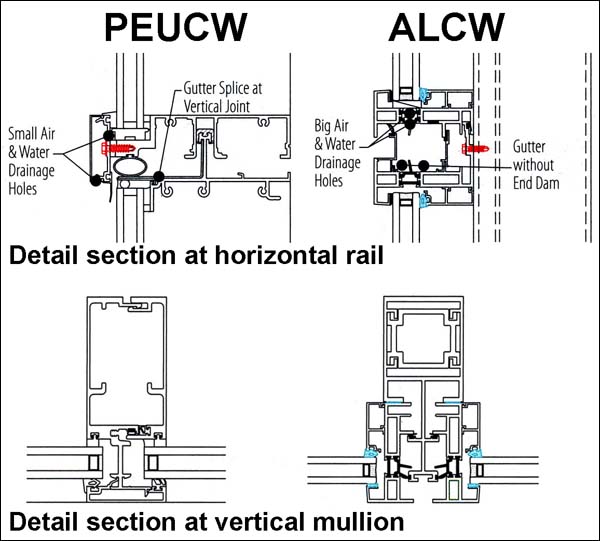

A May, 2012, article in the Construction Specifier titled Cause and Effect by Raymond Ting proposes "air loop" curtain walls (ALCW) instead of the pressure-equalized unitized curtain walls (PEUCW) described above. He points out that the PEUCW, while an improvement over non-pressure-equalized systems, still contains "critical seals" that can fail, and can result in staining on the exterior wall surface "due to the exposed drainage holes and the delayed drainage after diminishing of the positive wind pressure." (p. 38) One of the primary advantages cited for the ALCW systems is the uniformity of the panel unit design, whether at a typical vertical mullion position, at an inside corner, or at an outside corner: the same sealing detail is used for all conditions. This is accomplished by separating the structural mullion from the actual unitized glazed panel.

Ting proposed two strategies; he calls them "functional isolation concept" (FIC) and "unit design concept" (UDC). The former means that wall components should perform a single function, rather than multiple functions; the latter means that simplifying designs so that a single design can satisfy multiple conditions will eliminate numerous errors and problems in the field.

Ting also proposes to eliminate what he calls "critical seals" which are defined as follows: seals against both water and air at the same location; or a water-only seal having a path leading to an air seal.

Water leakage in a curtain wall may come about when any of these three things are present:

It is unrealistic to expect to solve this problem by providing a perfect (critical) seal on the entire curtain wall face, even using modern sealants. Having internal gutters is an improvement, but still requires numerous critical seals applied in the field (e.g., where the gutters are spliced together). Having a pressure-equalized unitized wall is a further improvement, but is still problematic.

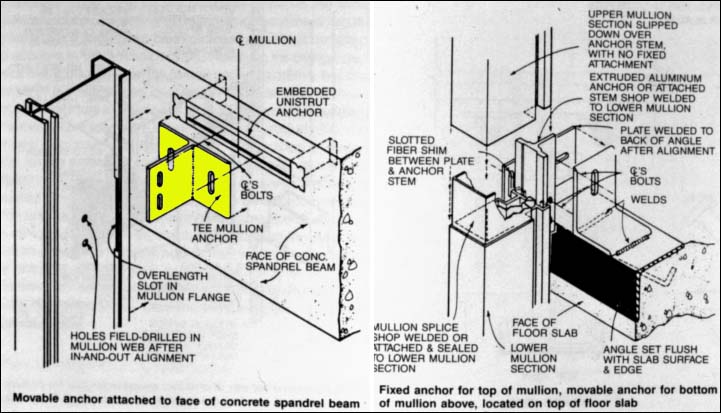

Like other forms of cladding attached to the structure by spanning from floor to floor, curtain wall mullions must be attached to resist gravity loads at one floor only. At the bottom (typically), the mullion slides over the mullion below it, allowing it to move vertically, but restraining it laterally.

![]()

Rubberized gaskets can also be used to support glazing, often attached to steel plates, as shown in the image below.

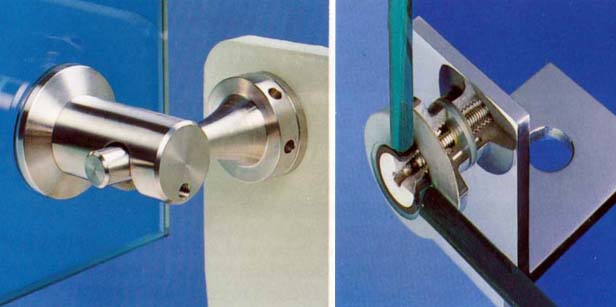

The idea that certain glazing systems are "structural" while others are not is misleading. Even so, the name, "structural glazing" has been assigned to certain systems that avoid or minimize the use of mullions and rails. The most "primitive" of such systems uses silicone sealant as a "glue" to attach glass lites to internal mullions.

A more sophisticated system, pioneered by Pilkington, supports each glass panel only at the corners, using special stainless steel fittings which are then held in place by some independent structural system. Glass "mullions" can also be used to transmit the loads of (and on) the glazing to the building structure. Joints between the glass panels are filled with silicone sealant.

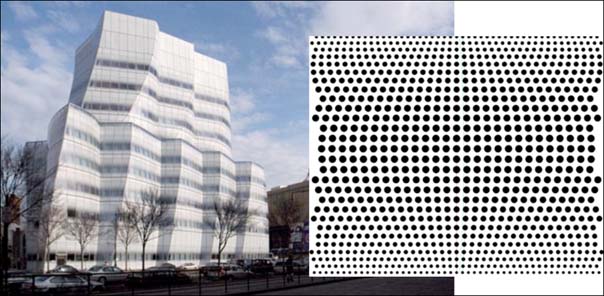

Bird collisions: Both clear and reflective glass pose enormous problems for migratory and other birds. In the case of clear glass, and depending on lines of sight, birds may see through the entire building and collide with the glazing attempting to reach the "natural" spaces (vegetation or sky) seen through the glass; in the case of reflective glazing, also depending on lines of sight and reflection, birds may see vegetation or sky reflected in the glazing and collide with the glazing not realizing that it is there. Fritted glass is one technique that can reduce such collisions. See this article and this article for additional information.

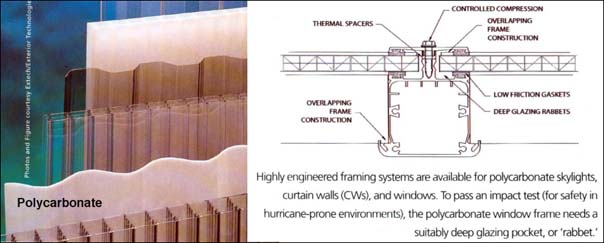

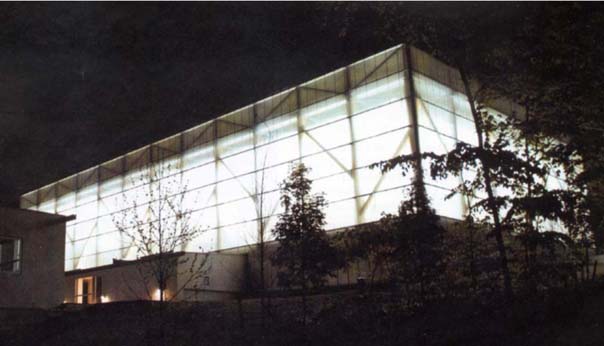

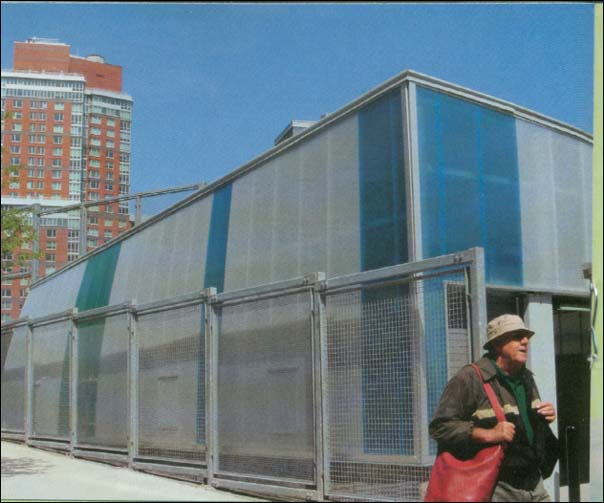

Various types of plastics are used as glazing, in particular acrylics (e.g., Lucite, Plexiglas) and polycarbonates (e.g., Lexan). They tend to be softer than glass, so more easily scratched. They have a larger coefficient of thermal expansion than glass; and are more resilient (less brittle).

Disclaimer: Students are responsible for material presented in class, and required material described on course outline. These notes are provided as a tentative outline of material intended to be presented in lectures only; they may not cover all material, and they may contain information not actually presented. Notes may be updated each year, and may or may not apply to non-current versions of course.

first posted Oct. 19, 2012 | last updated: Oct. 16, 2018

Copyright

2007–2012 J. Ochshorn. All rights reserved. Republishing material on this web site, whether in print or on another web site, in whole or in part, is not permitted without advance permission of the author.