Jonathan Ochshorn

First published as: Ochshorn, Jonathan, "On the Disappearance of Monolithic Walls: Meditations on a Brick," Making Environments: Technology and Design, pp.17-20 (© 1992 ACSA). Images, other than Figure 1, were added for this online version.

ABSTRACT

Traditional monolithic masonry wall construction has undergone a profound transformation since the development of the skeleton frame and the triumph of an integrated, layered and systematic approach to the construction of exterior walls. But the revolutionary change from a structural to a non-load-bearing status overshadowed the equally significant change in the role of the wall as an enclosure system. The development of the steel frame provided an incentive for the reduction of weight in the exterior wall, but it was primarily the refinement of the cavity wall as a response to the problem of moisture penetration, and the utilization of insulation to improve the performance of mechanical air conditioning systems that set the stage for a truly non-monolithic concept of the exterior wall. Although it met with some resistance rooted in metaphysical notions about the "nature of materials" and a Ruskinian aversion to the layering of systems on moral grounds, the transformation from monolithic to layered, heterogeneous exterior wall systems has had important repercussions. Technically, we see increased interest in pressure-equalized or "rain-screen" walls, in which the breakdown of traditional ideas about the integrity of the wall becomes the very premise for the enclosure strategy; formally, we see a continued interest in the appearance of monolithic masonry forms, but in a context which has long ceased to provide any performance-based rationale for their deployment; theoretically, we see the jettisoning of monolithic interpretations of works of architecture in favor of layered, multivalent readings — a process in many ways analogous to, if not directly related to, the disappearance of the monolithic wall in practice.

INTRODUCTION

Well into this century, brick and stone were the materials used, and bricklaying and stonemasonry were the construction technologies employed for the exterior walls of virtually all major structures. As opposed to more recent practice, these monolithic exterior wall systems did not readily sub-divide into distinct sub-systems, each with a separate purpose and identity. Rather than looking at the building structure, the various secondary structural systems supporting the (non-load-bearing) wall assembly, the barriers to air, water and vapor penetration, fireproofing, and thermal insulation as independent though integrated elements, what we see throughout virtually the entire history of architecture — at least from a purely technical point of view — is simply the monolithic masonry wall. The notion of the exterior wall as the primary element of construction was so ingrained that, according to one of the "various practical writers" on the subject of masonry and bricklaying in 1891, even "a floor may be in one sense said to be a wall, only posed or placed horizontally."1

It is well-known that this method of building underwent a dramatic transformation about 100 years ago with the development of the steel skeleton frame. Yet this revolution in building structure had remarkably little immediate impact on the wall itself, which for many years continued to be constructed in much the same way as it had before it lost its structural role. In fact the structural strength (i.e., the ability to withstand crushing) of brick and stone, at least for ordinary structures, was rarely a determining factor, even in the design of load-bearing walls.2

Sullivan's Carson Pirie Scott Building

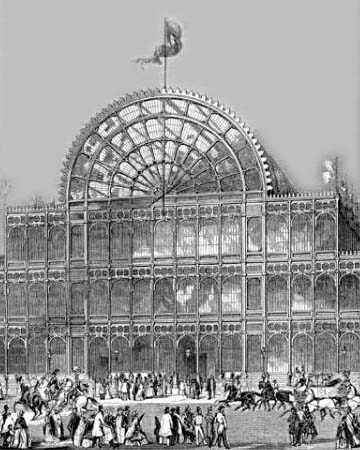

Paxton's Crystal Palace

Yet the potential to utilize wall systems that had no residual load-bearing attributes was clear at a relatively early date. The large panels of glass characterizing structures like Paxton's Crystal Palace of 1851, or of the various "Chicago frame" buildings from the late 1800s began to develop and express the technology of curtain walls even though, strictly speaking, Paxton was utilizing a "load bearing wall"3 and Sullivan and his peers still relied heavily on stone, brick and terra cotta to actually encase their steel frames. From our point of view, the primary lesson here was not the precise demarcation between curtain wall and bearing wall construction, or the use of masonry materials per se, but the creation of an alternative non-monolithic image for the exterior wall. Once the relative homogeneity of the traditional wall was successfully called into question by the parallel use of non-masonry (wood, metal and glass) wall systems, coupled with the developing materials science of the twentieth century, it was only a matter of time before the relentless integration of the various specialized systems characterizing today's exterior wall assemblies would transform this most basic architectural element.

Thus, the structural evolution in the exterior wall from load-bearing to column and girder does not, in and of itself, signal or explain the transformation of the exterior wall as enclosure system. On the one hand, the principles of separation and integration that characterize modern exterior wall systems can be seen developing prior to and independently of the development of the skeleton frame; on the other hand, the historically-ingrained idea of the monolithic wall persisted well beyond the moment at which it lost its load-bearing function.

But if the development of the modern curtain wall does not inevitably result from the revolution in framed structural systems, what then explains the apparent obsolescence of the traditional monolithic wall? This question will be examined by taking the common brick as the representative component of traditional exterior wall technology.

CHARACTERISTICS OF THE BRICK WALL

Using the humble brick as an example, several observations can be made about its characteristic attributes, some of which are also relevant to other traditional masonry systems. For example, the size of a brick is largely determined by four separate requirements, none of which has much to do with the performance criteria by which a modern exterior wall system would be judged: first, the requirement that a single bricklayer be able to comfortably lift and position one brick with one hand, freeing the other hand to work the mortar; second, limitations on the thickness of the brick based on the available manufacturing technology; third, the desirability of being able to construct various wall thicknesses (e.g., the traditional nine or fourteen inch wall) with a single module; and fourth, the necessity of proportioning the length (stretcher dimension) to the width (header dimension) according to a 2:1 ratio in order to implement the more usual bonding patterns, or simply to turn a corner without causing undo complications. To let these non-performance-based concerns control the very dimensions of the constructional module seems, from the point of view of modern integrated wall systems, like letting the tail wag the dog. But aside from the size of the module and various other attributes, it is the monolithic quality of the wall itself that is the major concern of this paper.

Lifting and positioning brick

Homogeneity. While there are countless variations on the basic type (e.g., bricks manufactured with distinct finishes, or hollow cross-sections) the traditional brick is a monolithic, rectangular solid of homogeneous composition. The major implication is self-evident: while there is certainly an array of structural, environmental and aesthetic issues associated with the use of any construction technology, there is no differentiation within the structure of the brick itself corresponding to these various concerns. It is mainly through the positioning of the brick units with respect to each other that these issues are dealt with, if at all.

In fact this observation can be generalized: traditional construction separates itself into many fewer "sub-systems" than does modern construction. The reasons are twofold. First, in traditional construction, single items perform multiple functions. In our example, the brick functions as load-bearing building structure, exterior finish, thermal insulation, water barrier, fireproofing, as well as the carrier of whatever aesthetic content can be extracted from the arrangement of the bonding pattern, the overall composition and the quality of the surface colors and texture. Secondly, certain functions are not addressed: with the benefit of hindsight, it is easy to demonstrate that things like electric power or mechanical air conditioning, which did not exist until fairly recently, were not among the issues to be dealt with in constructing buildings or building walls.

But although traditional construction technologies assign multiple tasks to single systems, they do so in a far different manner than do modern systems. This is because modern systems integrate separate pieces (each potentially addressing different and particular functions) to address multiple tasks, whereas in traditional construction, there is a tendency to manipulate or adjust one principle system to address these issues. The disintegration of the monolithic wall into discrete parts suggests that each of these parts might be "optimized" — whether in terms of some absolute performance criteria, or, what is more likely, in terms of performance relative to some other parameter, such as cost. On the other hand, the refinement of an essentially monolithic approach to accommodate multiple concerns inevitably results in a strategy of balance or compromise. No matter how clever the attempt, or how self-contained and integrated the result, the development of single-purpose products and their integration into wall systems has generally yielded superior performance at lower cost.4

Countervailing attitudes. There is, of course, an equally important and diametrically opposed generalization that can be made about the traditional construction of walls: that there were, in fact, strong tendencies to "layer" the wall with different sub-systems in response to a non-monolithic functional and aesthetic agenda. Gotfried Semper, one of the earliest proponents of this viewpoint, wrote that "the old tradition of coating the walls and all other parts of the construction remained universally valid throughout all periods up to Roman times, even when the walls were made of expensive materials such as marble and granite... only at a late stage of architectural development was the construction of the wall used as a decorative element."5

It could also be argued that even if such coatings were not applied to structures such as the Parthenon, the mere act of carving the stone created a surface or "layer" that was as conceptually distinct from the monolithic interior as any applied coating. The widespread use of facing stones or brick at the surface of walls otherwise composed mainly of concrete, rubble stone or common brick is another variation on this theme. Finally, the differentiation of interior finishes from the main body of the wall, whether through the use of wood, plaster, paint, tile or applied tapestries shows that the potential for looking at the wall as an integrated and layered system existed from, or even preceded, the earliest moment of building construction.

Adolph Loos

John Ruskin

What is interesting, therefore, is not that the beginning of a non-monolithic response to exterior wall construction can be traced to the primal origins of building itself, but that this attitude met with so much resistance precisely at the moment when its potential began to be realized. Related to the specifically "modern" objections noted earlier (see note 4), there is also the suspicion that, intrinsically, the layering of material in an assembly masks the true inner nature of that assembly with a deceptive veneer. Thus Ruskin suggests that the "painting of surfaces to represent some other material than that of which they actually consist..." is an "Architectural Deceit" to be avoided.6 Adolf Loos inverts this position by allowing any cladding that doesn't confuse itself with what it clads. But both of these stances actually have a common foundation in that they criticize the layering of construction systems, not from a technical, but from a moral point of view. Evidence that this ideological position found wide acceptance is abundant. To the un-named author of a home-study text on bricklaying published in 1891, a monolithic brick wall is superior to one coated with plaster because "it looks what it is, and carries no pretense with it. It is honest-looking work, which cannot be said of cemented work, with which, either from a constructive, an aesthetic, or a moral point of view — the latter when the purpose of cement is to deceive — we have not the slightest sympathy."7 Even where the constructive logic can no longer be questioned, the moral-aesthetic argument of Ruskin and Loos often remains: according to David Glasser's analysis of modern exterior insulation and finish systems, to encase a "functional package" [presumably everything in the building except the exterior wall system] with a "scenographic coating" [the exterior wall] is ethically "chilling."8

The aversion to layered wall systems is not absolute, however. One senses a distinction being made between materials whose formal appearance can be comfortably reconciled with some conceptual model of technical content (e.g., metal and glass curtain walls), versus materials either lacking conventional formal constraints (e.g., E.I.F.S.) or mimicking the formal qualities of other building technologies (e.g., cement scored to look like brick).

The focus on materials and their alleged "nature," rather than on objective environmental conditions and their mediation, is a recurring theme within the modern discourse on architecture. When Sigfried Giedion stated that "iron and glass are the two materials whose conjunction in nineteenth-century architecture led it to new solutions…"9 he set the stage for a pair of propositions that remained influential for many years. The first, criticized by Reyner Banham in his study of the "well-tempered environment," is the single-minded equation of technology with building structure;10 the second, whose roots go back considerably further, is the metaphysical notion that materials, per se, have a "nature" that seeks realization in works of architecture.

Saulnier's Chocolate Works

Thus, on the one hand, the non-structural hollow brick infill of Jules Saulnier's Chocolate Works was dismissed by Giedion as functioning "merely as filling"11 in contrast with the iron skeleton which was made to stand for the new technology. On the other hand, the moral imperative to give surfaces "force and expression by the frank use of undisguised materials…"12 was a more insidious reminder that the design of the exterior wall is a moral ("undisguised") and aesthetic ("expression") rather than a technical task.

In this ideological context, it is easy to understand the resistance to a layered and systematic approach to the design and construction of the exterior wall. Beyond the use of coatings to protect, mask or act as "environmental corrective"13 upon the essentially monolithic content of the wall, or the use of "monolithic" metal and glass systems which offered a competing but non-threatening version of the "frank use of undisguised materials," further applications of this layering principle were slow to materialize.

Adding a separate layer of insulation to exterior masonry walls was one such application. Here, as Banham points out, the structural benefits derived from reducing the weight of exterior walls in the new steel frame buildings (resulting in less thermal mass), coupled with the invention of mechanical air conditioning systems (whose economic performance suffered in buildings without adequate insulation), led to its incorporation.14

Moisture. But the problem of water penetration through masonry walls, and the resulting dampness of interior wall surfaces and spaces, was probably the single-most important stimulus to the breakdown of the monolithic masonry wall. Because brick and stone, as well as mortar, are permeable to water, traditional monolithic walls had to be quite thick to keep this water out. "With very thick brickwork the result was often satisfactory, moisture drying out sufficiently between periods of rain to prevent complete penetration to the inside."15 And for this drying to take place, relatively impermeable coatings were a potential problem, since the water which invariably would get in (whether from interior humidity or exterior leakage) would then have a hard time getting out: the conventional wisdom was "that solid masonry walls should have the capacity to 'breathe' if they are to remain watertight."16

But for brick walls that were not so thick, either because of the modest scale of the structure, or as a result of the pressure to reduce the weight of non-load-bearing exterior walls in skeleton construction, other means had to be found to prevent dampness from reaching the interior. One early innovation pre-dating the development of steel frame buildings was to project a number of bricks slightly beyond the face of the interior wall surface and to attach furring for a plaster finish to these projecting bricks, thereby creating an air space, or cavity, between the plaster and the brick wall which was fairly effective in stopping the migration of water from the exterior. Even well into the mid-twentieth century, variations on this approach were marketed: instead of wood lath, hard burned "Natco"-type split furring tiles were used in walls "exposed to the weather... The ribs being set against the wall, an air space is formed, which effectively checks the passage of moisture."17

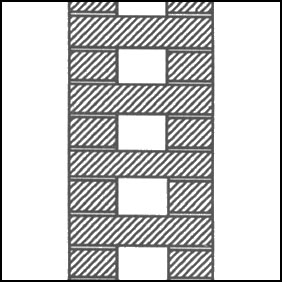

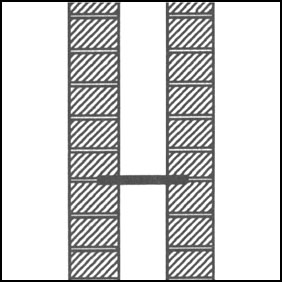

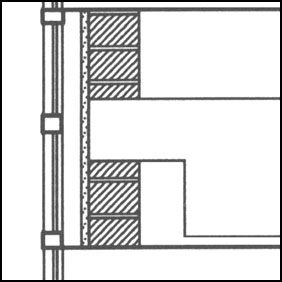

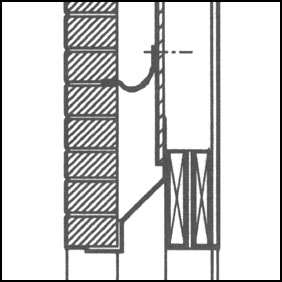

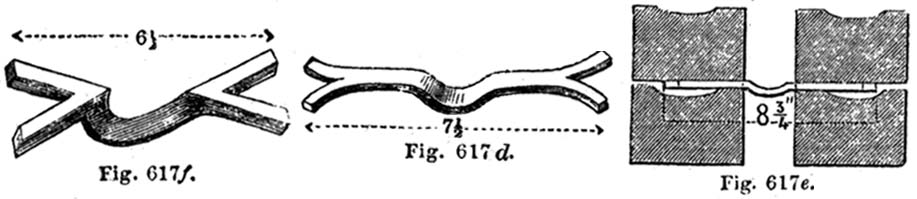

Cavity walls to achieve the same result originated in the early nineteenth century; the first primitive version took the traditional "Old English" bonding pattern and modified it by placing the alternating stretcher courses "on edge" rather than "on bed," thereby creating intermittent air spaces between the monolithic header courses.18 But it was not until after 1912 that a separate non-brick sub-system, specifically metal ties, began to replace the through-wall brick headers that had been used to stabilize these hollow walls since 1829.19 The replacement of brick with metal is significant: with the provision of an independent sub-system replacing the inter-tier bonding function of the brick, it became possible to re-formulate the conceptual structure of the wall itself. In other words, once the various properties of the brick could be isolated as separate parameters, each potentially replaceable by more efficient purpose-built sub-systems, the erosion of the monolithic wall concept was inevitable.

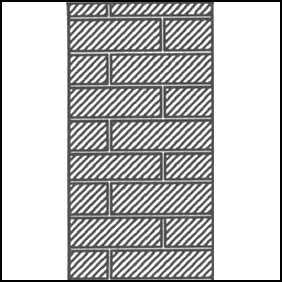

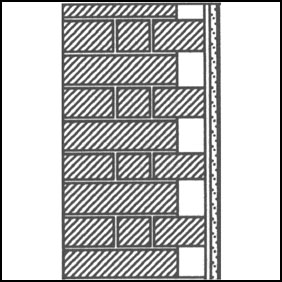

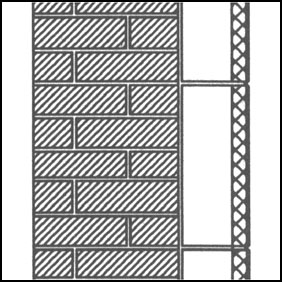

(a)

(b)

(c)

(d)

(e)

(f)

(g)

(h)

Figure 1. The problem of water penetration was probably the sigle-most important stimulus to the breakdown of the monolithic wall. Key steps in the evolution of layered wall systems were: (a) 12" monolithic brick wall; (b) projecting bricks and furring to create air space; (c) "Natco"-type split furring tiles on 12" brick wall; (d) first "hollow" wall of 1829; (e) cavity wall with metal ties; (f) curtain wall with masonry backup (Lever House, 1951); (g) masonry veneer on non-masonry backup; (h) layered, non-masonry sysstem (E.I.F.S.). Drawings by the author.

CONCLUSION

The disintegration of the monolithic masonry wall gained its first real impetus from the use of furring to control moisture penetration and the gradual evolution of these wood or tile furring systems into full-blown cavity walls in which metal ties stabilize two separate tiers of masonry. Simultaneously, the pressure to reduce the weight of these walls in high-rise framed structures led to the widespread use, beginning in about 1915, of composite walls typically consisting of face brick backed up directly with hollow tile.20 These developments opened up within the wall a literal as well as conceptual space in which a layered and systematized approach to the problem of enclosure could gain a foothold. Once the monolithic masonry wall was split in two and the task of connecting the two halves assigned to an independent sub-system, a number of possibilities presented themselves. Just five years after metal ties appeared, the first metal and glass "curtain wall" was built. Originating in 1917 with the Hallidie Building in San Francisco, and maturing in the 1950s with structures like Lever House or the U.N. Building in New York, this ubiquitous cladding system was conceptually just a variation on the masonry cavity wall in which the exterior facing tier of masonry that had characterized all previous major structures was entirely replaced with non-masonry materials, leaving the masonry back-up primarily for fireproofing. Conversely, in later variations, the back-up tier was replaced with a non-masonry (e.g., metal stud) support system, leaving a single thickness of brick (or stone) veneer at the exterior. And once new fireproofing materials and systems were developed to prevent the spread of fire from floor to floor, the complete elimination of masonry from the exterior walls of major buildings became an option for the first time.

U.N. Secretariat Building

SOM's Lever House

Polk's Hallidie Building

The outcome of this transformation has been profound. From a technical point of view, we see increased interest in pressure-equalized or "rain-screen" walls, in which the breakdown of traditional ideas about the integrity of the wall becomes the very premise for the enclosure strategy, and in which all vestiges of a monolithic attitude are removed. Simultaneously, recent research involving "phase-change materials" within a layered, non-monolithic building skin has called into question even the thermal mass advantages of monolithic masonry.21 From a formal point of view, we see a continued interest in the bonding patterns, structural geometries, surface texture and color, in short, the appearance of monolithic masonry. But this has occurred in a technical context which has long ceased to provide any conceptual support for these forms, stone and brick alike having been reduced to the moral equivalent of "skin" in modern exterior wall systems.

From a theoretical point of view there has been, at least up till now, a tendency to downplay the purposeful incongruities between form and its technological basis. Whether grounded in the practice of monolithic masonry or based upon other building technologies, the desire to transcend the apparent limitations of constructional materials and thereby confound the prevailing expectations of what is technically possible or appropriate, can often be read into works of architecture. But this reading presupposes a comparison — the urge to transcend constructional norms is implicitly measured against the "craft familiarity with the behavior of wood, stone, brick …," to use Banham's terminology, that each culture inherits and re-creates. The significance of the breakdown of monolithic models of the form-defining wall may well be that this point of comparison, this "transparent" underlying knowledge of the technical basis for the conventional use of materials, is no longer present in many of the the layered heterogeneous systems we use.

Some recent theoretical speculations on architecture have analogues in this changing building technology. As an example, consider the claim that "the idea of text in general and more specifically, a dislocating text... removes the restraint of morality, that is the responsibility of form to the traditions of architecture."22 Moral constraints (specifically, the requirement that form express something about its technological basis) appear, in fact, to be less sustainable since the disengagement of surface from "content," always a plausible abstraction, has become an inescapable reality within the layered, non-monolithic technological systems themselves.

This disembodied reality characterizes not only modern exterior wall systems, but also a large part of architectural theory. While this shift in theoretical perspective certainly has sources outside of building technology (and well beyond the scope of this paper) it is at least worth noting this coincidence: the fracturing of monolithic interpretations of works of architecture into layered or multivalent readings has followed, even if indirectly, the invention of layered construction systems and the virtual disappearance of the monolithic wall.

NOTES

1 The Stonemason and the Bricklayer, by various practical writers, edited by the editor of "The Industrial Self-Instructor," Ward, Lock, and Co.(New York, NY) 1891, p.3.

2 "…for ordinary small houses any modern building brick is much stronger than necessary for its job... The history of building in brick appears to offer only one instance of disaster caused by too low a crushing strength..." Woodforde, John Bricks: To Build a House Routledge & Kegan Paul (London) 1976, pp.15-16. See also Gwilt, Joseph The Encyclopedia of Architecture, 1867 edition Crown Publishers (New York, NY), p. 390: "The crushing of stone and brick, by mere superimposed weight, is of extremely rare occurrence in practice, even with soft stone and with bad bricks."

3 Bonzon, Philip G., "Metals in Cladding: Past - Present - Future," Proceedings of the 1989 Fall Symposium: Exterior Claddings on High Rise Buildings, Report No. 12 (The Chicago Committee on High Rise Buildings) 1990, p.187.

4 This notion concerning the superior performance of modern systems has been challenged on various grounds, most commonly, by suggesting that non-performance-based criteria can profoundly effect our response to materials and systems: "The mainstream theory of architecture... has failed to give any general coherent explanation of the values necessary for building well... I have just been working on some blocks of concrete we are making for a building in the Sierras... The concrete is massive. You feel its weight… What is this—this activity? It is an ancient thing, a heavy thing, nothing like the thing we call architecture now... Yet it is these stones that are what architecture really is." Alexander, Christopher, "Manifesto 1991" Progressive Architecture July 1991, pp. 108-109. Kenneth Frampton takes a more tempered view by acknowledging the potency of modern systematized technology, but suggesting that an opposing force ought to be drawn from local practice: "…the mediation of universal technique [through a "Critical Regionalism"] involves imposing limits on the optimization of industrial and postindustrial technology." Frampton, Kenneth, "Towards a Critical Regionalism" The Anti-Aesthetic: Essays on Postmodern Culture, Hal Foster, ed., Bay Press (Seattle) 1983, p.21. Peter McCleary explains the aversion to "opaque" non-monolithic systems by suggesting that architects, having "derived their theories, for the most part, from buildings of the past," would tend to prefer "the transparency of arts and crafts to the opacity of machine reproduction." McCleary, Peter, "Some Characteristics of a New Concept of Technology" JAE Fall 1988, p.6. Finally, Demetri Porphyrios has emphasized the need to relate form to building materials and technique [perhaps an impossibility when the technique itself no longer operates according to the familiar methods associated with the use of traditional materials]: "Building & Architecture," Building & Rational Architecture Architectural Design AD Editions (London) 1984, p.31.

5 Semper is quoted in Herrmann, Wolfgang Gotfried Semper: In Search of Architecture MIT Press (Cambridge, MA) 1984, pp.210-211.

6 Ruskin, John The Seven Lamps of Architecture Noonday Press (New York, NY) 1974, p.39.

7 The Stonemason and the Bricklayer, op. cit., pp.253-254.

8 Glasser, David Evan, "Curtains for the Wall", Proceedings of the Symposium on Architecture and ACSA Technology Conference '89 (Baton Rouge, Louisiana) 1989, p.257.

9 Giedion, Sigfried Space, Time and Architecture: The Growth of a New Tradition Harvard University Press (Cambridge, MA) 1941) p.113.

10 Banham, Reyner The Architecture of the Well-Tempered Environment, 2nd edition, The University of Chicago Press (Chicago, Illinois) 1984, pp.9-10.

11 Giedion, op. cit., p.138.

12 Giedion, ibid., p.334.

13 "The occupants of buildings were made comfortable, if at all, by the application of knowledge that was implicit in a kind of craft familiarity with the behavior of wood, stone, brick, and adobe, understood primarily as structural necessities with inevitable environmental consequences, and of certain other materials, notably textiles, understood primarily as environmental corrective…" Banham, op. cit., p.293. [emphasis added]

14 Banham, op. cit., pp.71-73.

15 Handisyde, C.C. and Haseltine, B.A. Bricks and Brickwork The Brick Development Association (London) undated, p.31.

16 Mulligan, John A. Handbook of Brick Masonry Construction McGraw-Hill Book Co. (New York, NY) 1942, p.401.

17 Mulligan, ibid., p. 339.

18 The Stonemason and the Bricklayer, op. cit., p. 249.

19 This date for the first use of metal ties in a cavity wall is found in: Woodforde, op. cit., p.13.

[added 5/26/06: I have subsequently found a reference to earlier use of metal ties ("hoop-iron cramps") in brick "hollow walls... at Southampton, and perhaps elsewhere" presumably in the mid-1800s, although a precise date is not given. See Joseph Gwilt, Encyclopedia of Architecture ("Classic" 1867 edition), Crown Publishers, Inc. (New York, NY) 1982, p.555 for description and the following illustration, including a note that the "bend in the middle" helps "prevent any moisture running along it to the inside face."]

20 Mulligan, op. cit., p.314.

21 Forrest Wilson, "The Changing Nature of Building Skins," Architecture (March 1989), p. 69.

22 Eisenman, Peter, "Architecture as a Second Language" Restructuring Architectural Theory Diani and Ingraham, eds., Northwestern University Press (Evanston, Illinois) 1989, p.73

First posted 12 April, 2006; last updated 25 January, 2008 [minor re-formatting]