Jonathan Ochshorn

© 2007 Jonathan Ochshorn.

Following is my summary and critique of the "Indoor Environmental Quality" section of the LEED 2.2 New Construction Reference Guide, Second Edition, Sept. 2006. My commentary on the Reference Guide can be found in the red boxes below, and within each of the chapters linked immediately above.

The argument for improving indoor air quality relies primarily on economic factors, viewed from the standpoint of a business owner seeking to improve productivity and reduce liability: "The use of better products and practices has reduced potential liability for design team members and building owners. The results are increased market value… and greater productivity for the occupants." Actual well-being of occupants is understood as a product, in part, of daylighting and views to the exterior.

The required baseline for indoor air quality (IAQ) is defined by ASHRAE 62.1-2004, Ventilation for Acceptable Indoor Air Quality (sections 4-7). Naturally ventilated buildings (i.e., those relying on windows or "passive ventilation" rather than on mechanical equipment or "active" ventilation) are also covered in that standard. For these passive buildings, spaces must be within 25 feet of a window (or roof opening) which must provide a "vent" area equal to at least 4% of the occupied floor area. These requirements are standard operating procedure in many places; in those cases, "no additional design effort or capital cost will be required to meet this prerequisite."

LEED's baseline prerequisite for IAQ sets the bar pretty much where it already is.

ETS is another name for "secondhand" smoke. There are three options for compliance: either prohibit smoking in the building and limit outside smoking to designated areas at least 25 feet from entries or windows; or allow smoking inside within designated smoking areas which are sealed, de-pressurized, and exhausted to the exterior while also having the same outside smoking limits as in the first option; or, for residential occupancies only, prohibit smoking in common areas, limit outside smoking as in the other options, make sure all penetrations between dwelling units are sealed, and either weatherstrip doors to corridors or maintain positive pressure in corridors relative to dwelling units.

This is a bit strange to have in a sustainability guideline, since it is impossible to assess its impact. Nothing prevents the current building owner, or a new owner, from changing a smoking policy. On the other hand, smoking is already prohibited in many buildings by state or local law.

The idea is to monitor indoor air quality by measuring CO2 levels either directly in densely-occupied spaces (with at least 1 person per 40 sq.ft.), or in non-dense spaces at points where air is exhausted. Anything measured above 10% of "setpoint" must set off an alarm to maintenance personnel or occupants. Note that ASHRAE standards have recently been lowered with respect to IAQ, so that the "traditional" 1,000 ppm indoor setpoint for CO2 may no longer be required in some building zones. Note that average values for exterior CO2 range from 300 to 500 ppm.

This is another instance where the baseline for LEED compliance is set arbitrarily low; so low, in fact, that EQ Credit 2 mandates more fresh (make-up) air than would be required for Credit 1. Even Credit 2 is viewed as a compromise between what is needed and what is "practical."

The requirement varies for active and passive systems:

For mechanically-ventilated spaces, provide 30% more outdoor air than mandated per ASHRAE 62.1-2004 (i.e., 30% more than Credit Prerequisite 1 requirements).

For naturally-ventilated spaces, comply with "Carbon Trust Good Practice Guide 237 (1998)" as well as some certain requirements (per Fig. 1.18) of the "Chartered Institution of Building Service Engineers (CIBSE)" Applications Manual 10:2005, Natural Ventilation in non-Domestic Buildings," while demonstrating compliance with either the CIBSE recommendations or the "macroscopic, multi-zone, analytical model" in ASHRAE 62.1-2004, chapter 6.

This increased ventilation rate is admittedly lower than what research findings suggest would be necessary to achieve acceptable IAQ, i.e., 25 cfm/person ventilation rates, equivalent to an increase of 50% over the ASHRAE (and Credit Prerequisiste 1) requirements. The LEED commentary admits that "30% was chosen as a compromise between indoor air quality and energy efficiency." In other words, one can get 2 LEED points for IAQ without adequately protecting occupant health. The idea that increased ventilation rates necessarily improve indoor air quality is however — and paradoxically — questionable. Joseph Lstiburek writes: "My insider's perspective (on Standard 62.2 at least) is that there is a lot of mileage to be made by scaring people about underventilation, and folks are rising to the occasion. Unfortunately, overventilation in hot, humid climates has led to more indoor air problems due to mold resulting from part-load issues than underventilation anywhere else... Doesn't anyone at the U.S. Green Building Council know anything about energy and part-load humidity?" (ASHRAE Journal, August 2008, p.64).

Two points are available for dealing with IAQ at the (1) construction and (2) pre-occupancy phases.

RE: construction, a plan must be developed with the following goals:

Comply with Sheet metal and air conditioning contractors national association (SMACNA) IAQ guidelines, 1995, chapter 3.

Protect absorptive materials from moisture.

Any building air handlers used during construction must be filtered with a minimum efficiency reporting value (MERV) of 8 at each return grille, and replaced prior to occupancy. Note that LEED also warns contractors that such use "activates the manufacturer's warranty [of HVAC equipment], exposing contractors to potential out-of-pocket costs…"

Specify low-toxicity paints, carpets, etc. (also covered in EQ Credit 4).

Ventilate VOC-emitting materials directly outside.

RE: pre-occupancy, the required plan for the 2nd LEED point is more rigorous:

Flush out. In general, fresh air needs to be supplied at a rate of 14,000 cubit feet per square foot of floor area (with internal temperature at least 60 degrees F and relative humidity no more than 60%) before the building is occupied. Where occupancy needs to happen before a complete flush-out, different, but equivalent, procedures are specified.

Test air: Optionally, one can test the air quality before occupancy, per the Compendium of Methods for the Determination of Air Pollutants in Indoor Air of USEPA and LEED guidelines, to comply with these maximum pollutant levels:

formaldehye @ no more than 50 parts per billion

particulates (PM10) @ no more than 50 micrograms per cubic meter

total volatile organic compounds (TVOC) @ no more than 500 micrograms per cubic meter

4-phenylcyclohexene (4-PCH) @ no more than 6.5 micrograms per cubic meter [this applies only when styrene butadiene rubber used commonly as a carpet backing is installed in base building]

The LEED rationale for improving IAQ is that increasing worker productivity translates to "greater profitability for companies…" at least relative to those businesses that prefer to save energy by supplying stale air to building occupants. This trade-off between energy cost and indoor air quality is made explicit elsewhere in the LEED guidelines, so that the claim here that IAQ improvements, in and of themselves, lead to "greater profitability" is contradicted by the admission that the added costs of heating and cooling fresh air may outweigh any productivity gains. The idea that increased IAQ necessarily leads to greater productivity is also questionable, especially where workers do not get paid sick leave (this includes approximately half of all full-time private sector workers in the U.S.). When sick workers don't get paid, productivity (a measure of output per amount invested) doesn't necessarily suffer, since either remaining workers will pick up the slack (actually increasing productivity), or temporary workers will fill in (leaving productivity unchanged).The suffering of workers — admittedly increased by conditions of poor air quality — cannot simply be equated with reduced productivity of capital.

Even where a certain allowance is made for sickness (e.g., company policies or legislation mandating a certain number of "sick days"), this simply becomes the new "baseline" factored into business calculations; in this context as well, improved worker health due to improved IAQ does not necessarily translate into increased rates of output (productivity). Studies that purport to show productivity gains due to increased indoor air quality are often flawed, in that they do not actually measure productivity, but rather measure health improvements which are then carelessly extrapolated into productivity claims. For example, given a potential reduction in respiratory illness of 9% to 20% based on improved indoor air quality, one scholarly study [PDF] concludes that "16 to 37 million cases of common cold or influenza would be avoided each year in the US. The corresponding range in the annual economic benefit is $6 billion to $14 billion." This so-called "benefit" is calculated by multiplying the average wages of the workers studied (apparently $375 per sickness) by "16 to 37 million" incidents of colds or flu per year. But it is not at all clear that this "benefit" is lost, or, if it is lost, who the loser is: to repeat the point made above, when sick workers are not paid, productivity may actually increase (as fellow workers pick up the slack), or at least stay more or less the same as replacement workers are hired.

Another criticism of productivity claims — according to Anne Whitacre's letter in the February 2008 issue of The Construction Specifier — is that "worker productivity goes up when employees move to a new office space, but that the result is often short-lived." She concludes that "since most green buildings have been around for less than five years, any long-term studies of costs and productivity are simply not yet available." I haven't been able to independently confirm this claim.

Practices that damage worker health have always been perfectly compatible with both productivity and profitability (see, for example, this NY Times Op Ed by Susan J. Lambert from Sept. 19, 2012). It is always state intervention (40-hour week, child labor laws, and so on) that establishes the baseline conditions for acceptable damage to worker health, compatible with growth of the economy as a whole. While it may be true that competition for the highest-level elite workers impels owners in such industries to offer higher-quality interior environments, low levels of indoor air quality for the rest of the work force threaten neither productivity nor profitability.

The intention of this credit is to reduce the emission of harmful contaminants associated with various building materials. One point is available in each of the following four categories applicable, in general, to interior construction only:

Adhesives and sealants: must comply with South Coast Air Quality Management District (SCAQMD) Rule #1168 and, for aerosol adhesives, with "Green Seal Standard for Commercial Adhesives GS-36.

Paints and coatings: must comply with SCAQMD VOC limits for clear wood finishes, floor coatings, stains, sealers, shellacs; Green Seal Standard GS-11 for paints, coatings, and primers; and Green Seal Standard GC-03 [sic] for anti-rut paints.

Carpet systems: comply with requirements of the Carpet and Rug Institute's Green Label Plus program, while simultaneously meeting the adhesive standards listed above.

Composite wood and agrifiber products: must be produced with no added urea-formaldehyde resins. Note that exterior products are commonly made with phenol formaldehyde which, unlike urea-formaldehyde, does not off-gas at normal temperatures; they are therefore considered acceptable under these guidelines. Included are such things as plywood, particle board, medium-density fiberboard, and so on.

This credit seeks to reduce the ongoing contamination of occupied space, not from construction materials, but from exterior pollutants and interior processes that release hazardous gases. To get this point requires compliance with all of the following:

Provide 6-foot long entry mat, grate, grille, etc. to capture dirt and other particulate matter.

Treat any space in which hazardous gases or chemicals are present much like designated smoking areas (Prerequisite 2): floor-to-deck sealed partitions, negative pressure, and direct exhaust to the exterior. Note that "convenience" copiers and printers are excluded.

Where mechanical ventilation is used, process both supply air, and any return air that will become supply air; and use pre-occupancy filters with MERV = 13 or better (not just MERV = 8 as in Credit 3).

This credit consists of two points, one each for providing de-centralized control of lighting and heating/cooling.

Lighting: To comply, lighting controls must be provided for 90% of occupants (individual users) and for 100% of all multi-occupant spaces, so that lighting can be adjusted to suit particular tasks according to individual preferences.

Thermal comfort (heating/cooling): To comply, "comfort control" must be provided for 50% of occupants (individual space users) and for 100% of multi-occupant spaces. Such controls can be hi-tech or low-tech (e.g., operable windows count), and can address any one of the four thermal comfort parameters:

air temperature

radiant temperature

air speed

humidity

This credit has a "design" and "verification" component, each worth one point.

Design: Meet ASHRAE Standard 55-2004 Thermal Comfort Conditions for Human Occupancy. Document compliance per section 6.1.1. of this standard. Also, coordinate with Prerequisite 1 and EQ Credits 1 and 2. LEED understands these EQ credits as constituting a "challenge" for green buildings, since they tend to increase energy use.

The contradiction ("challenge") of reducing energy while promoting indoor air quality is acknowledged in the LEED guidelines, but not resolved. Energy and IAQ are, in fact, linked; yet LEED allows them to be treated independently. There is no penalty under the LEED guidelines for choosing to save energy at the expense of indoor environmental quality. At the extreme, even if none of the 12 EQ credits are complied with, there are still plenty of points left for platinum certification.

Verification: Compliance with the design intention of this credit point is determined by surveying occupants 6-18 months after the building is completed. Per the ASHRAE standard cited above, 20% or greater occupant dissatisfaction requires that the thermal issues be addressed and fixed.

A survey conducted six months after occupancy will not necessarily reveal thermal problems that are seasonal in nature, e.g., overheating in the summer, or cold indoor temperatures in the winter. It will also not guarantee that building operators will maintain adequate comfort levels in the years after such a survey is conducted.

This credit deals with glass and glazing from two points of view, and allows 1 point for each: (1) bringing daylight inside, and (2) providing views to the outside (1 point).

Daylight: The basic criterion is to supply daylight to 75% of the building's regularly-occupied interior spaces. This is defined in three different ways, any of which can be used to demonstrate compliance:

GF = (window area / floor area) x (window geometry factor) x (actual Tvis / minimum Tvis) x (window height factor).

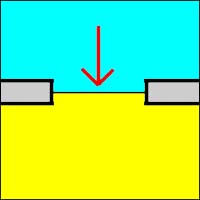

In this equation, Tvis is the visible light transmittance defined as the ratio of transmitted light to total incident light (where "light" is the visible spectrum, i.e., having wavelengths of 380-780 nanometers). The minimum value is shown in the table below, adapted from the LEED guidelines, along with geometry and height factors for five typical window/skylight configurations (from top to bottom: side light with daylight glazing, side light with vision glazing, top light vertical monitor, top light sawtooth monitor, and top light horizontal skylight):

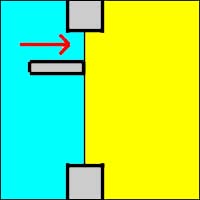

| Diagram | Geometry factor | Minimum Tvis | Height factor | Glare control |

|---|---|---|---|---|

|

0.1 | 0.7 | 1.4 | blinds, light shelves, exterior shading |

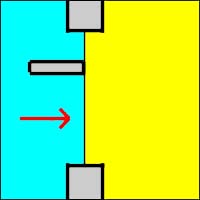

|

0.1 | 0.4 | 0.8 | blinds, exterior shading |

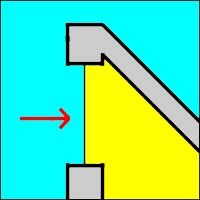

|

0.2 | 0.4 | 1.0 | fixed interior blinds, adjustable exterior blinds |

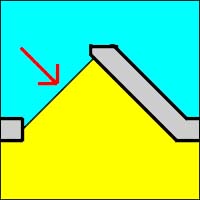

|

0.33 | 0.4 | 1.0 | fixed interior blinds, adjustable exterior blinds |

|

0.5 | 0.4 | 1.0 | interior or exterior fins, louvers |

Use computer simulation to prove that daylighting provides 25 footcandles of illumination (assuming clear sky, noon, equinox, measured 30" above floor) in the required 75% of spaces.

Same as option 2, but use actual measurements of illumination levels (on a 10-foot grid) instead of computer simulation. Only rooms that comply completely can contribute to the 75% square footage requirement.

Note that glare control is also a critical aspect of this credit.

Views: The basic criterion is to provide a direct line of sight to outdoor space via "vision glazing" (i.e., glazing positioned between 2'-6" and 7'-6" above the floor) for 90% of the occupants of regularly occupied areas. Note that the entire area of a single-person space counts if at least 75% of the space meets the "sight line" criteria; and that the entire space does not count if less than 75% of the area complies. On the other hand, only the actual compliant areas (i.e, those areas within the room where sightlines can be drawn through windows) count in multi-occupant spaces.

First posted Nov. 2, 2007; last updated 21 September, 2012 [added link to NY Times Op Ed]